Introduction

In the quest for sustainable materials, waterborne polyurethane has emerged as a game changer in various industries. This innovative coating solution not only boasts impressive performance characteristics but also aligns with eco-friendly practices. To truly appreciate the significance of waterborne polyurethane, we must first explore its composition and applications, along with the different types of polyurethane available.

Understanding Waterborne Polyurethane

So, what is a waterborne polyurethane? It is a type of polymer that uses water as its primary solvent, making it more environmentally friendly compared to traditional solvent-based polyurethanes. This unique formulation provides excellent adhesion, flexibility, and durability while minimizing harmful emissions during application.

The Importance of Sustainable Coatings

The growing awareness around environmental sustainability has prompted industries to seek out alternatives to conventional coatings. Sustainable coatings like waterborne polyurethane not only reduce VOC emissions but also contribute to healthier indoor air quality and lower environmental impact. As consumers become increasingly conscious of their choices, the demand for eco-friendly solutions continues to rise.

Dive into Types of Polyurethane

When discussing polyurethane, it’s essential to understand that there are three main types: thermosetting, thermoplastic, and bio-based formulations. Each type serves distinct purposes across various applications; however, waterborne polyurethane stands out due to its versatility and eco-friendliness. By exploring what are the three types of polyurethane and their respective advantages, we can better appreciate how they fit into sustainable practices.

What is Waterborne Polyurethane?

Waterborne polyurethane is a versatile coating material that has gained traction in various industries due to its eco-friendly properties. But what exactly is a waterborne polyurethane? This innovative formulation uses water as a primary solvent, which significantly reduces volatile organic compounds (VOCs) compared to traditional polyurethane options. The result is a product that not only offers durability and flexibility but also aligns with the growing demand for sustainable solutions in coatings.

Composition and Characteristics

The composition of waterborne polyurethane typically includes polyols, diisocyanates, and additives, all suspended in a water-based system. This unique blend allows it to maintain excellent adhesion and abrasion resistance while being less harmful to the environment. Additionally, characteristics such as quick drying times and low odor make it an appealing choice for both manufacturers and consumers alike.

Comparison with Traditional Polyurethane

When comparing waterborne polyurethane to traditional polyurethane, the differences are striking. Traditional formulations often rely on organic solvents that can release harmful VOCs into the atmosphere, posing health risks during application and curing. In contrast, waterborne variants offer similar performance characteristics—like durability and chemical resistance—without the environmental baggage associated with their solvent-based counterparts.

Advantages for Eco-Friendly Applications

The advantages of using waterborne polyurethane for eco-friendly applications are manifold. Not only does it minimize air pollution during application, but it also reduces waste through its efficient use of resources. Furthermore, innovations like Bio-Based Waterborne Polyurethane are paving the way for even greener alternatives by incorporating renewable materials into their formulations, thus enhancing sustainability without compromising quality or performance.

What are the Three Types of Polyurethane?

Polyurethane is a versatile material that comes in various forms, each with its unique properties and uses. Understanding the three primary types of polyurethane—thermosetting, thermoplastic, flexible, and rigid—is crucial for selecting the right type for specific applications. This section will explore these categories in detail, shedding light on their characteristics and industrial applications.

Thermosetting vs. Thermoplastic

When discussing polyurethane types, it’s essential to differentiate between thermosetting and thermoplastic varieties. Thermosetting polyurethane undergoes a chemical change when cured, resulting in a hard structure that cannot be remolded or reshaped upon heating. In contrast, thermoplastic polyurethane remains pliable when heated and can be reshaped multiple times without losing its integrity, making it ideal for applications requiring flexibility.

Understanding these differences helps answer questions like What is a waterborne polyurethane? as many waterborne formulations are designed to offer the best of both worlds—combining easy application with durability. This knowledge is also vital when considering What is the application of waterborne polyurethane? since the choice between thermosetting or thermoplastic can significantly impact performance in various environments.

Flexible and Rigid Polyurethane Explained

Within these two categories—thermosetting and thermoplastic—polyurethane can further be classified into flexible and rigid types based on their density and intended use. Flexible polyurethanes are typically used in cushioning applications like furniture upholstery or automotive interiors because they provide comfort while retaining shape over time. Rigid polyurethanes, on the other hand, are often utilized in insulation panels or structural components where strength is paramount.

The distinction between flexible and rigid polyurethanes also plays a role when discussing waterborne formulations; many manufacturers aim to produce eco-friendly options that retain flexibility without compromising durability or performance under moisture exposure. This leads us back to queries such as Does water damage polyurethane? which highlights the importance of selecting appropriate materials for specific environmental conditions.

Usage Across Various Industries

The versatility of polyurethane makes it an essential material across numerous industries—from construction to automotive manufacturing to consumer goods production. Waterborne polyurethane coatings are particularly favored due to their low VOC emissions and environmentally friendly properties, making them suitable for furniture finishes or flooring solutions where sustainability is key.

Moreover, industries are increasingly turning towards bio-based waterborne polyurethane options as they seek greener alternatives without sacrificing quality or performance standards—a trend worth noting given today’s focus on sustainable practices. As we continue exploring What is a waterborne polyurethane? we see how these innovations cater specifically to industry needs while addressing environmental concerns effectively.

What is the Application of Waterborne Polyurethane?

Waterborne polyurethane has carved a niche in various industries due to its versatility and eco-friendly properties. From furniture coatings to automotive interiors, the applications of waterborne polyurethane are vast and impactful. Understanding what is the application of waterborne polyurethane can help businesses make informed choices about sustainable materials.

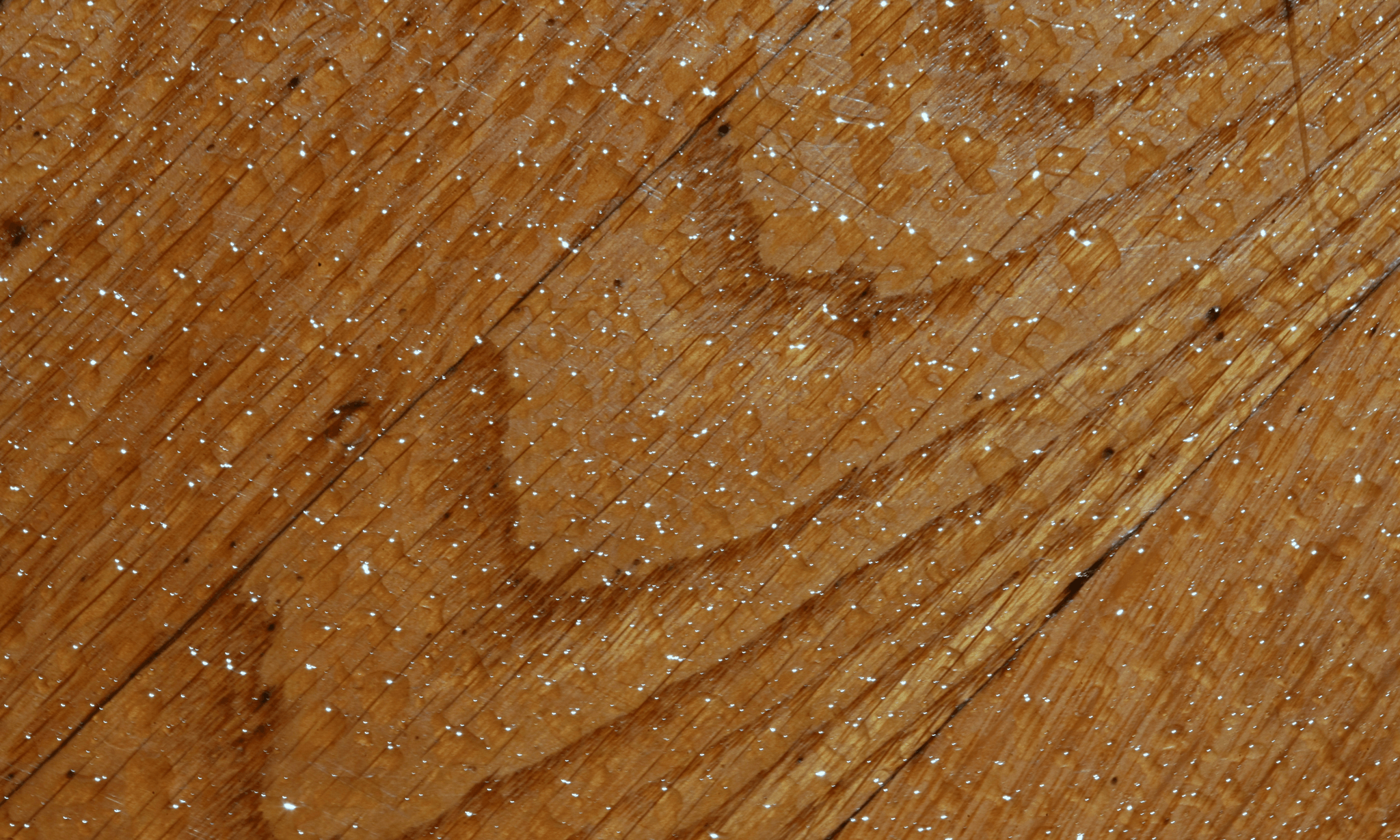

Coatings for Furniture and Flooring

This type of coating not only enhances the aesthetic appeal but also provides a durable finish that withstands daily wear and tear. By opting for waterborne polyurethane, you get a product that is low in volatile organic compounds (VOCs), making it safer for indoor environments—what’s not to love about that?

Moreover, these coatings are easy to apply and dry quickly, allowing for efficient production processes without sacrificing quality. Whether it’s hardwood floors or stylish wooden furniture, waterborne polyurethane ensures long-lasting protection while maintaining a vibrant look. With its increasing popularity, many consumers are now asking: what is a waterborne polyurethane? The answer lies in its impressive performance characteristics.

Automotive Interiors and Electronics

Waterborne polyurethane's applications extend far beyond just furniture; it's also making waves in automotive interiors and electronics. In vehicles, this material provides an attractive finish while offering excellent resistance to scratches and chemicals—perfect for high-traffic areas like dashboards or seats. Additionally, its flexibility allows it to adapt well to different surfaces without compromising durability.

In the realm of electronics, manufacturers are turning to waterborne polyurethane for coating components that require protection against moisture and dust. This adaptability makes it an ideal choice across various sectors within automotive manufacturing as well as consumer electronics. As industries increasingly prioritize sustainability, understanding what is the application of waterborne polyurethane becomes crucial.

Baolite's Role in Waterborne Solutions

Baolite has emerged as a key player in providing innovative solutions centered around waterborne polyurethane technology. By focusing on developing high-quality formulations that meet both environmental standards and performance requirements, Baolite exemplifies how companies can lead the charge toward sustainable practices—what are the three types of polyurethane? Well, Baolite seems committed to advancing all types with eco-friendly options.

Their research into bio-based formulations further enriches their offerings by blending sustainability with functionality—truly embodying what bio-based waterborne polyurethane stands for! With their expertise in creating tailored solutions, Baolite plays an essential role in promoting wider acceptance of these advanced materials across industries worldwide. The question remains: does water damage polyurethane? Thanks to innovations from companies like Baolite, we can confidently say that modern formulations offer better resistance than ever before.

Does Water Damage Polyurethane?

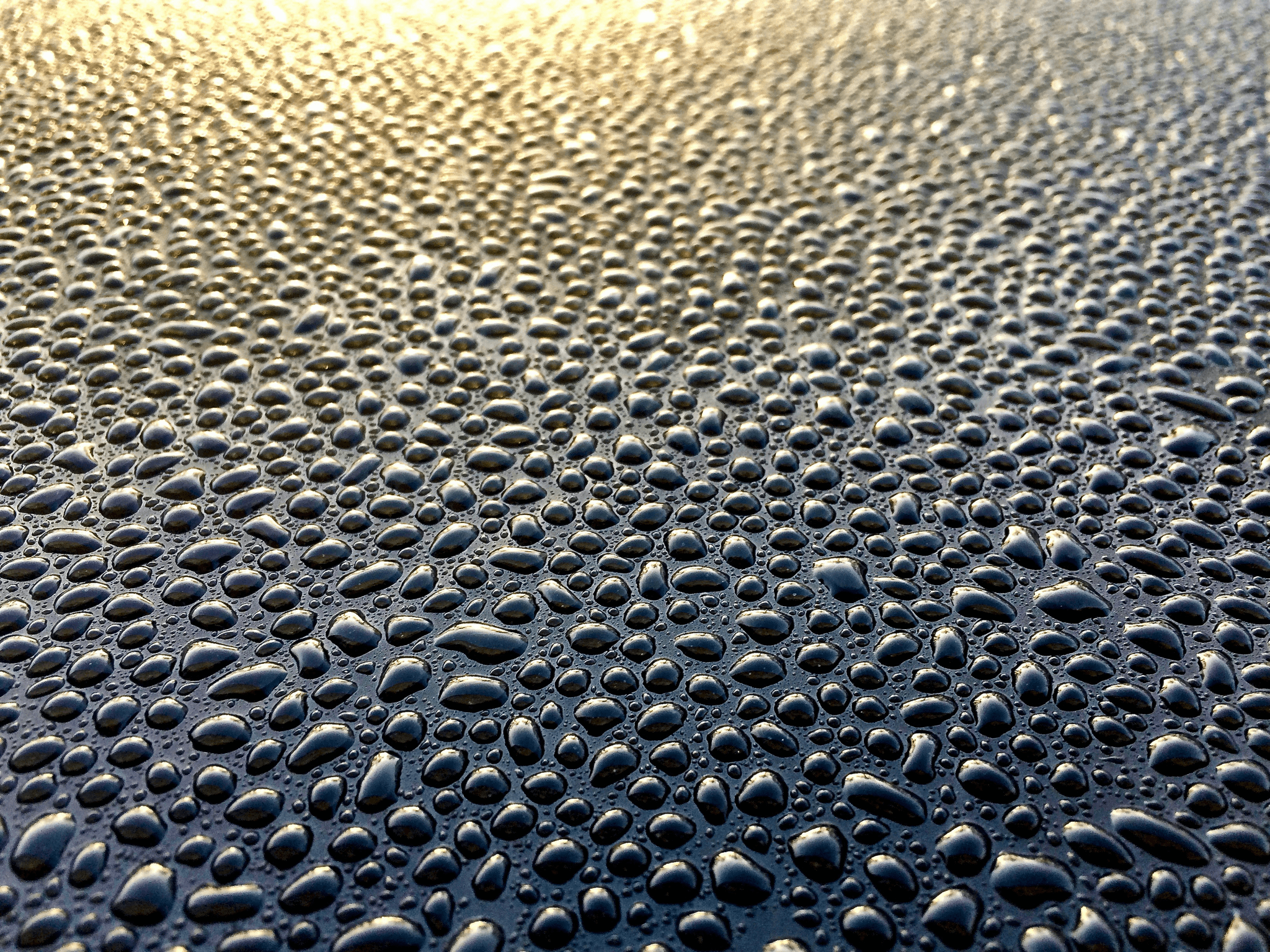

Understanding Water Resistance

Waterborne polyurethane offers a degree of water resistance, but that doesn’t mean it’s entirely waterproof. The formulation allows for moisture vapor transmission while providing a protective layer against liquid spills and humidity. However, prolonged exposure to standing water can compromise its integrity, leading to potential bubbling or peeling—definitely not the look you want for your newly coated furniture or flooring!

Maintenance Tips for Longevity

To ensure the longevity of your waterborne polyurethane application, regular maintenance is key. Clean surfaces with mild soap and warm water rather than harsh chemicals that could degrade the finish over time. Additionally, applying a fresh coat of waterborne polyurethane every few years can help maintain its protective qualities and keep surfaces looking brand new.

Impact of Environmental Factors

Environmental factors such as temperature fluctuations and humidity levels can significantly impact the performance of waterborne polyurethane. High humidity may cause the coating to soften or weaken, while extreme cold could lead to brittleness over time. It’s crucial to consider these factors when deciding on applications—especially in areas subject to drastic weather changes—to ensure that your investment in this versatile material stands the test of time.

Bio-Based Waterborne Polyurethane

In recent years, the push for sustainable materials has led to the development of bio-based waterborne polyurethane. These innovative formulations utilize renewable resources, such as plant-based oils and starches, to create products that are not only effective but also environmentally friendly. By reducing reliance on petroleum-derived components, bio-based waterborne polyurethane presents a compelling alternative in the quest for greener solutions.

Benefits of Bio-Based Formulations

The primary advantage of bio-based formulations is their reduced environmental impact. Unlike traditional waterborne polyurethane, which often relies on non-renewable resources, these eco-friendly alternatives contribute to a lower carbon footprint by utilizing sustainable raw materials. Additionally, they often exhibit enhanced biodegradability and lower toxicity levels, making them safer for both users and the environment.

Another noteworthy benefit is that bio-based waterborne polyurethane can maintain high performance standards across various applications. Whether used in coatings or adhesives, these formulations deliver durability and flexibility comparable to their conventional counterparts. Furthermore, manufacturers can market their products as eco-conscious options, appealing to an increasingly environmentally aware consumer base.

Innovations in Eco-Friendly Production

The production of bio-based waterborne polyurethane has seen significant advancements thanks to innovations in chemistry and material science. Researchers are continuously exploring new methods to enhance the efficiency of converting biomass into usable polymers without compromising quality or performance. These innovations not only improve production processes but also lead to cost-effective solutions that can compete with traditional materials.

Moreover, companies are investing in technology that minimizes waste during manufacturing while maximizing resource utilization—an essential aspect of creating sustainable products like bio-based waterborne polyurethane. The integration of green chemistry principles into production processes ensures that harmful solvents and additives are kept at bay, promoting a cleaner environment throughout the lifecycle of the product.

Case Studies from Leading Manufacturers

Several leading manufacturers have embraced bio-based waterborne polyurethane with remarkable success stories showcasing its potential across various industries. For instance, a prominent furniture manufacturer adopted this eco-friendly coating solution for its product line—resulting in not only improved sustainability credentials but also enhanced customer satisfaction due to superior performance attributes.

Another case study highlights an automotive company that incorporated bio-based waterborne polyurethane into its interior components and upholstery—offering consumers a greener choice without sacrificing quality or durability. These examples demonstrate how embracing innovations in eco-friendly production can lead to tangible benefits for both businesses and consumers alike.

Conclusion

In summary, waterborne polyurethane represents a significant advancement in the realm of sustainable coatings. By understanding what is a waterborne polyurethane and its applications, we can appreciate its role in various industries while also recognizing its eco-friendly advantages. As we look to the future, it’s clear that innovations in this field are not only beneficial for manufacturers but also for our planet.

Key Takeaways on Waterborne Polyurethane

Waterborne polyurethane stands out due to its unique composition and characteristics, making it an excellent choice for environmentally conscious applications. When exploring what is the application of waterborne polyurethane, we find it used extensively in furniture coatings and automotive interiors, showcasing its versatility. Additionally, understanding what are the three types of polyurethane helps clarify how waterborne options fit into broader categories like thermosetting and thermoplastic materials.

Future of Sustainable Coatings Solutions

The future of sustainable coatings solutions is bright as more manufacturers embrace bio-based waterborne polyurethane formulations. These innovative products not only reduce environmental impact but also meet the growing demand for eco-friendly materials across various sectors. As consumers become more aware of their choices, understanding does water damage polyurethane becomes crucial; hence, developing resilient formulations will be key to maintaining performance over time.

The Role of Innovation in Material Development

Innovation plays a pivotal role in material development, particularly with bio-based waterborne polyurethane leading the charge toward sustainability. Constant advancements ensure that products remain effective while minimizing ecological footprints—an essential balance for modern manufacturing practices. Ultimately, as we explore what is a waterborne polyurethane and delve deeper into its capabilities and applications, it becomes evident that innovation will drive the industry forward.