Introduction

Adhesive glue might seem like a straightforward topic, but the world of bonding agents is rich with variety and complexity. From everyday crafts to industrial applications, understanding the different types of adhesive glue is crucial for achieving optimal results. Whether you're wondering how to seal a blister pack or selecting the right medical blister adhesive, knowing your options can make all the difference.

Understanding Adhesive Glue Types

There’s no shortage of adhesive glue types available today, each designed for specific purposes and materials. By familiarizing yourself with these options, you’ll be better equipped to tackle any project that requires reliable adhesion.

Importance of Choosing the Right Adhesive

Choosing the right adhesive glue is essential not just for ensuring strong bonds but also for enhancing safety and efficiency in your projects. The wrong choice can lead to subpar results, from failed seals in packaging to compromised medical applications. Thus, understanding how to seal a blister pack properly or selecting an appropriate laminating adhesive for blister pack solutions becomes paramount in avoiding costly errors.

Common Mistakes in Adhesive Selection

Many individuals make common mistakes when selecting their adhesives—often overlooking essential factors such as material compatibility and environmental conditions. For instance, using a standard adhesive glue instead of a specialized medical blister adhesive could lead to ineffective bonding in critical applications. By being aware of these pitfalls and taking time to research your options, you can ensure that every project achieves its intended outcome without unnecessary hiccups.

Types of Adhesive Glue

Overview of Popular Adhesives

Adhesive glue comes in a myriad of forms, each tailored for specific uses. Some of the most common types include cyanoacrylate (super glue), polyvinyl acetate (PVA), and epoxy resin. Each adhesive has its strengths; for instance, super glue dries quickly and forms a strong bond on various surfaces, while PVA is ideal for woodworking due to its flexibility and ease of use.

Epoxy is another heavyweight contender in the adhesive arena, known for its exceptional strength and resistance to environmental factors. It’s commonly used in construction and repairs where durability is paramount. Understanding these options helps you choose wisely based on your project needs—be it sealing a blister pack or crafting intricate models.

When to Use Epoxy vs. PVA

Knowing when to use epoxy versus PVA can save you time, frustration, and possibly even money in the long run! Epoxy is your go-to choice when you need a robust bond that can withstand heavy loads or harsh conditions; think outdoor furniture or structural repairs. On the other hand, if you're working on arts and crafts or light woodworking projects—especially if you're wondering how to seal a blister pack effectively—PVA might be your best bet due to its ease of use and clean-up with water.

Another factor worth considering is curing time: epoxy often requires longer curing times but offers superior strength once set. PVA dries relatively quickly but may not provide the same level of bonding power under stress conditions as epoxy does. Ultimately, selecting between these two adhesives depends on your specific application requirements; both have their rightful place in any adhesive toolkit.

Benefits of Chemix's Water-Based Resin Solution

One significant advantage is its versatility; whether you're bonding paper products or plastics, this resin adapts well without compromising performance. Plus, being water-based means easier cleanup compared to solvent-based alternatives—no more wrestling with harsh chemicals after completing your project! As sustainability becomes increasingly important in our choices today, opting for products like Chemix’s water-based solution can make a positive impact while still delivering reliable results.

Understanding Application Needs

Assessing Your Project Requirements

Before diving into the world of adhesive glue, it's essential to evaluate what you're working on. Are you sealing a blister pack or perhaps looking for a medical blister adhesive? Each project has its nuances; knowing whether you need flexibility, strength, or resistance to elements will guide your choice effectively.

For instance, if you're dealing with packaging that requires durability and protection from tampering, a laminating adhesive for blister pack solutions might be ideal. On the other hand, if you're working in a healthcare setting where sterility is paramount, opt for specialized medical blister adhesives that meet stringent safety standards. By clearly outlining your project requirements upfront, you'll set yourself up for success.

How to Seal a Blister Pack Effectively

So how do you seal a blister pack effectively? The first step involves selecting the right adhesive glue based on the materials involved—plastic and foil often require different approaches! Make sure to clean both surfaces thoroughly before application; any dust or grease can compromise adhesion.

Once you've prepared your surfaces and chosen an appropriate laminating adhesive for your blister pack needs, apply it evenly across the sealing area. Use pressure during application to ensure proper bonding—this is especially important when using medical blister adhesives that must maintain integrity under various conditions. Finally, allow adequate curing time as recommended by the manufacturer; patience pays off in achieving a strong seal!

Factors Influencing Adhesive Performance

Several factors influence how well an adhesive performs in any given application. First and foremost is compatibility; not all adhesive glues work well with every material combination. For example, using a standard PVA glue on certain plastics may result in poor adhesion compared to specialized options like medical blister adhesives designed specifically for such tasks.

Environmental conditions also play a role—temperature and humidity can affect curing times and overall bond strength significantly. Additionally, consider load-bearing requirements: some projects demand stronger bonds than others; thus selecting an appropriate laminating adhesive for your blister pack is vital if it will bear weight or stress over time. Keeping these factors in mind will help you choose wisely and achieve optimal results!

Specialty Adhesives for Unique Uses

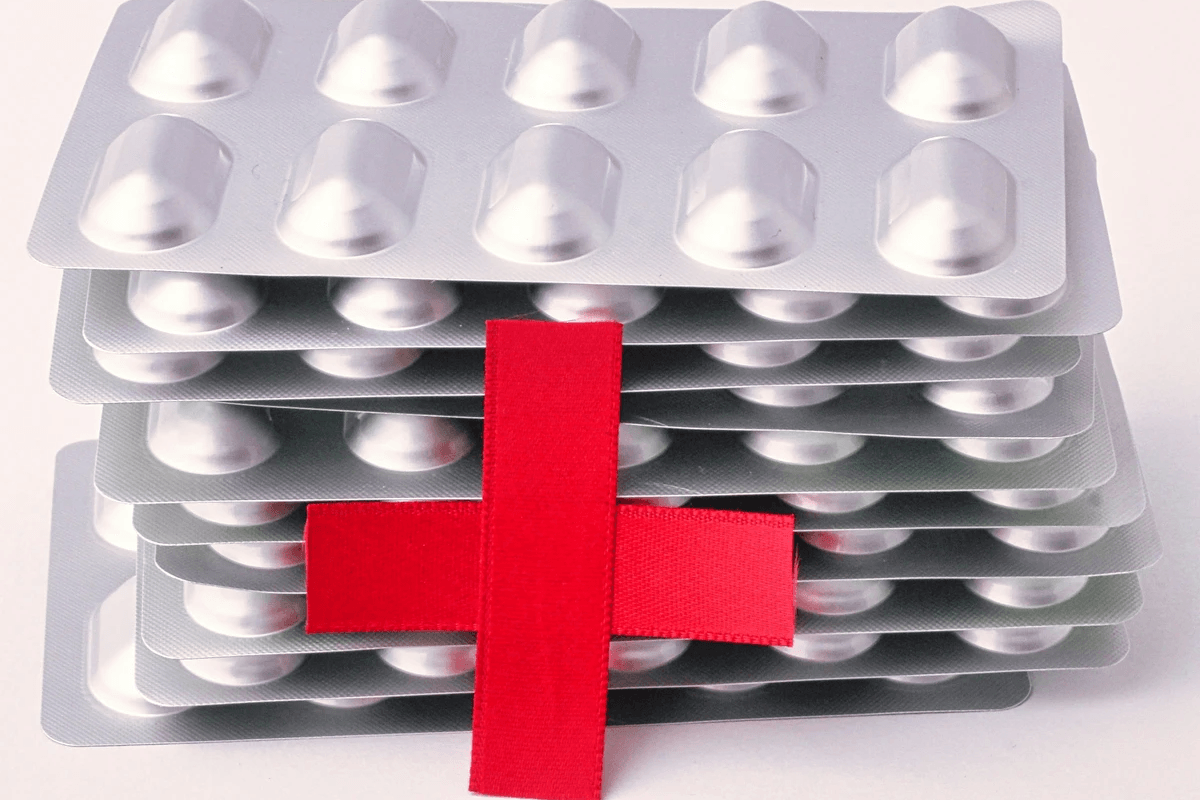

Exploring Medical Blister Adhesive Options

Medical blister adhesive is designed with patient safety and comfort in mind, often used for securing dressings or drug delivery systems. These adhesives are hypoallergenic and breathable, ensuring that they won’t irritate sensitive skin while maintaining strong adhesion. When selecting a medical blister adhesive, it’s crucial to consider factors such as moisture resistance and the duration of wear; after all, who wants an uncomfortable experience when healing?

Understanding how to seal a blister pack effectively can also hinge on the choice of medical adhesives. Many products come in pre-formed designs that minimize application errors while maximizing effectiveness. The right medical blister adhesive can ensure that medications remain protected until they’re ready for use.

Laminating Adhesive for Blister Pack Solutions

Laminating adhesive for blister pack solutions plays a vital role in packaging integrity and product safety. This type of glue is specifically formulated to bond multiple layers together, creating a barrier that protects contents from environmental factors like moisture and oxygen. Choosing the right laminating adhesive ensures that your blister packs not only look professional but also perform reliably during transport and storage.

When exploring options for laminating adhesives, consider their compatibility with various materials such as PVC or PETG films commonly used in blister packaging. The proper selection will enhance durability while ensuring that the package remains easy to open—a win-win situation! Additionally, understanding how to seal a blister pack effectively requires knowledge about curing times; some adhesives may need longer periods before achieving full strength.

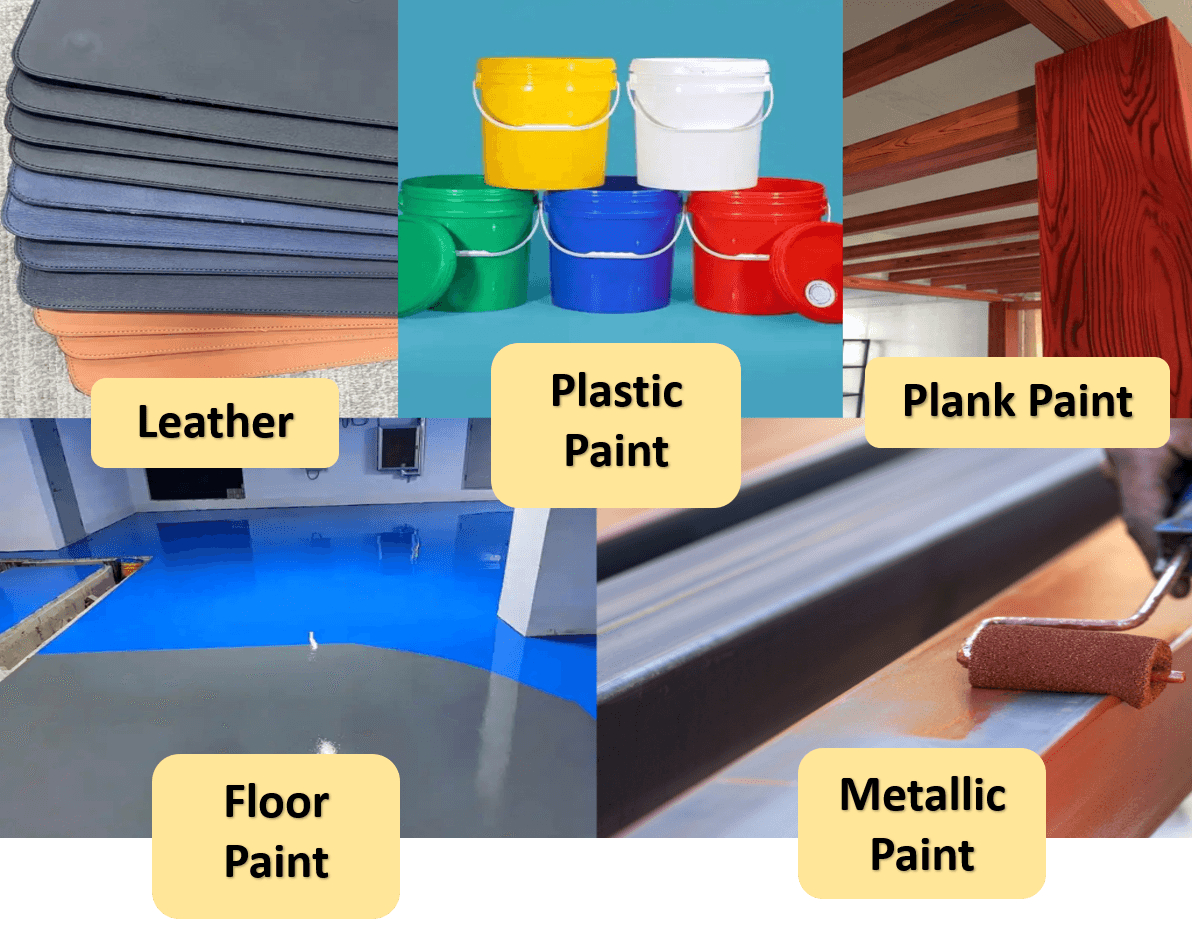

Choosing Adhesives for Industrial Applications

In industrial settings, selecting the appropriate adhesive glue can significantly impact production efficiency and product quality. Industrial adhesives must withstand extreme conditions including temperature changes, chemical exposure, and mechanical stress—so choosing wisely is essential! Whether you're bonding metals or plastics in manufacturing processes or assembling components in construction projects, there’s an adhesive tailored just for you.

For instance, epoxy-based glues offer exceptional bonding strength ideal for heavy-duty tasks while water-based options provide easier cleanup without sacrificing performance—perfect when working with laminating adhesive for blister pack solutions! Always assess your specific application needs; this will guide you toward an optimal choice that enhances productivity without compromising quality.

Environmental Considerations

In today's world, the environmental impact of our choices has never been more critical, and adhesive glue is no exception. Selecting eco-friendly options can significantly reduce our carbon footprint while still providing effective bonding solutions. Understanding the available choices in sustainable adhesives can empower consumers and industries alike to make better decisions.

Eco-Friendly Adhesive Options

When it comes to eco-friendly adhesive glue, there are several options that stand out from the crowd. Water-based adhesives are a popular choice because they contain fewer volatile organic compounds (VOCs), making them less harmful to both the environment and human health. Additionally, natural adhesives derived from plant sources, such as starch or casein, provide a biodegradable alternative suitable for many applications.

For those wondering how to seal a blister pack sustainably, consider using bio-based laminating adhesive for blister pack solutions that minimize environmental impact without compromising performance. These adhesives offer excellent adhesion properties while being kinder to the planet. By opting for eco-friendly adhesive options, you can contribute to a greener future without sacrificing quality.

The Rise of Sustainable Adhesives

The demand for sustainable adhesives has surged in recent years as industries recognize their responsibility towards the environment. Manufacturers are now focusing on developing innovative formulations that maintain performance while reducing harmful ingredients found in traditional adhesive glue products. This shift not only benefits the planet but also meets consumer expectations for environmentally responsible products.

Among these innovations are medical blister adhesive options designed with sustainability in mind—ensuring that even healthcare packaging adheres to eco-friendly standards without compromising safety or efficacy. As awareness grows about plastic waste and pollution from conventional adhesives, more companies are investing in research and development of sustainable alternatives that cater to diverse needs across various sectors.

Impact of Adhesive Choices on Health

The choice of adhesive glue can have significant implications for health—both directly through exposure during application and indirectly via environmental contamination over time. Many traditional adhesives release VOCs that can lead to respiratory issues or allergic reactions upon prolonged exposure; thus, selecting low-VOC or non-toxic alternatives is essential for safety-conscious consumers and professionals alike.

Moreover, when considering how to seal a blister pack effectively while prioritizing health, it's vital to choose materials free from harmful chemicals often found in conventional laminating adhesive for blister pack applications. By making informed decisions about your adhesive selections, you not only protect your health but also contribute positively to overall public well-being by reducing hazardous substances released into our surroundings.

Tips for Effective Adhesive Application

Preparing Surfaces for Bonding

Before you even think about applying your adhesive glue, it's crucial to prepare the surfaces that will be bonded together. Cleanliness is next to stickiness; make sure surfaces are free from dust, grease, and moisture as these can significantly weaken the bond. For projects like sealing a blister pack, consider using isopropyl alcohol or another suitable cleaner to ensure both surfaces are pristine before applying any medical blister adhesive.

Surface texture also plays an important role in adhesion; rougher surfaces often provide better grip than smooth ones. If you're dealing with materials that have glossy finishes or coatings, lightly sanding them can enhance adhesion by increasing surface area for the glue to grip onto. Remember—preparation isn’t just half the battle; it’s the whole war when it comes to effective bonding!

Ensuring Proper Curing Times

Now that you've got those surfaces ready, let's talk curing times—because patience is indeed a virtue in the world of adhesives! Each type of adhesive glue has its own set of curing requirements that you should follow closely for optimal results. For instance, while some adhesives might set quickly, they may require additional time to fully cure and reach their maximum strength.

If you're using laminating adhesive for blister packs or any other specialized glue, always refer back to the manufacturer's guidelines regarding curing times and conditions. Rushing this process could lead to weak bonds or even complete failure of adhesion down the line—definitely not something you want after putting in all that hard work! So take a breath, step away from your project if needed, and let those adhesives do their magic.

Troubleshooting Common Adhesive Issues

Even with careful preparation and attention to curing times, issues can still arise when working with adhesives—don’t worry; it happens! One common problem is inadequate bonding due to insufficient surface preparation; if you find your medical blister adhesive isn’t sticking as expected, double-check those surfaces! Another frequent issue involves improper curing conditions such as temperature fluctuations or high humidity levels which can hinder performance.

If you've applied laminating adhesive for blister packs but notice bubbling or peeling after application, it might be time for some troubleshooting magic: try reapplying under controlled conditions where temperature and humidity are stable. And remember—if at first you don’t succeed with your chosen adhesive glue method, don’t hesitate to explore alternative options tailored specifically for your project needs!

Conclusion

In the world of adhesive glue, making informed choices is crucial for successful projects. Whether you're sealing a blister pack or selecting a medical blister adhesive, understanding the various options available can save time, effort, and resources. By keeping key factors in mind and avoiding common pitfalls, you can ensure that your adhesive selection meets both your immediate needs and long-term goals.

Key Takeaways for Adhesive Selection

When selecting adhesive glue, it's essential to consider the specific requirements of your project. For instance, if you're wondering how to seal a blister pack effectively, you'll want to choose an adhesive that provides strong bonding while maintaining product integrity. Additionally, understanding the differences between laminating adhesive for blister pack solutions and other types of adhesives can help you make smarter decisions tailored to your application.

Another important takeaway is recognizing the performance characteristics of each type of adhesive glue. Factors such as drying time, temperature resistance, and flexibility play significant roles in determining which glue will work best for your project. Always remember that thorough surface preparation can enhance adhesion quality—so don’t skip this vital step!

Final Thoughts on Sustainable Adhesives

As we become more environmentally conscious, the demand for sustainable adhesives is on the rise. Eco-friendly options are not only better for our planet but can also provide excellent performance without compromising safety or effectiveness—especially when it comes to specialized uses like medical blister adhesive applications. Embracing sustainable adhesives doesn't mean sacrificing quality; it means choosing products that align with modern values while still delivering outstanding results.

Moreover, as industries continue to innovate in developing greener alternatives, staying informed about these advancements will be beneficial for anyone involved in adhesive selection processes. It’s worth exploring how laminating adhesive for blister pack solutions can now include eco-friendly formulations that meet both regulatory standards and consumer expectations without leaving a negative footprint.

Resources for Further Learning on Adhesives

To deepen your knowledge about different types of adhesive glue and their applications, numerous resources are available online and offline. Websites dedicated to DIY projects often feature comprehensive guides on how to seal a blister pack effectively using various adhesives suited for different materials and conditions. Furthermore, industry publications frequently provide insights into emerging trends in specialty adhesives such as medical blister adhesives.

Books focused on materials science or industrial applications also serve as valuable references when navigating complex bonding challenges with adhesives like laminating adhesive for blister packs or other unique uses you may encounter in your projects. Don't hesitate to join forums or social media groups where enthusiasts share tips and tricks related to all things sticky!