Introduction

When working with polyurethane, choosing the right adhesive is crucial for achieving strong and durable bonds. Whether it's wood adhesive glue for woodworking projects or polyurethane adhesive for plastic surfaces, the selection process requires careful consideration of various factors. In addition to traditional adhesives, exploring the benefits of using water-based resin solution can offer eco-friendly and sustainable advantages in adhesive applications.

Understanding the Importance of Choosing the Right Adhesive for Polyurethane

Selecting the appropriate adhesive for polyurethane is essential to ensure optimal bonding strength and durability. The unique properties of polyurethane require a specialized adhesive that can effectively bond with its surface, whether it's wood or plastic. Using the wrong type of adhesive can result in weak bonds and compromised structural integrity, making it crucial to understand the importance of choosing the right one.

Key Factors to Consider When Applying Adhesive for Polyurethane

Applying adhesive for polyurethane involves considering key factors such as surface compatibility, curing time, and environmental impact. Wood adhesive glue should be carefully selected based on its ability to bond effectively with different types of wood, while polyurethane glue needs to adhere well to plastic surfaces without compromising strength or flexibility. Understanding these factors is essential for successful application and long-lasting bonds.

When choosing an adhesive for polyurethane, it is important to also consider the specific application requirements, such as temperature resistance and impact strength. Additionally, proper surface preparation and application techniques are crucial for achieving a strong and durable bond. Taking the time to carefully assess these factors will ultimately result in a successful and reliable adhesive application for polyurethane materials.

Exploring the Benefits of Using Water-Based Resin Solution

In addition to traditional adhesives, exploring water-based resin solutions offers numerous benefits in terms of sustainability and environmental responsibility. Water-based resin solutions provide a safer alternative to solvent-based adhesives, reducing volatile organic compound (VOC) emissions and promoting eco-friendly practices in adhesive applications.

Selecting the Right Adhesive for Polyurethane

When choosing wood adhesive for polyurethane, it's essential to consider factors such as the type of wood, the application method, and the environmental conditions. Different types of wood may require different adhesives to ensure a strong and durable bond. Additionally, considering the specific requirements of the project, such as moisture resistance or flexibility, will help determine the most suitable wood adhesive for polyurethane.

Understanding the properties of polyurethane adhesive is crucial in selecting the right adhesive for polyurethane applications. Polyurethane adhesives offer excellent strength and flexibility, making them suitable for a wide range of materials including wood and plastic. Their ability to withstand varying temperatures and environmental conditions makes them a popular choice for many bonding applications.

The benefits of using water-based resin solution in adhesive applications are numerous. Water-based resin solutions offer low odor, easy clean-up, and excellent adhesion properties when used as an additive in wood adhesive glue or polyurethane glue. They also contribute to reducing harmful emissions and promoting environmentally friendly practices in manufacturing processes.

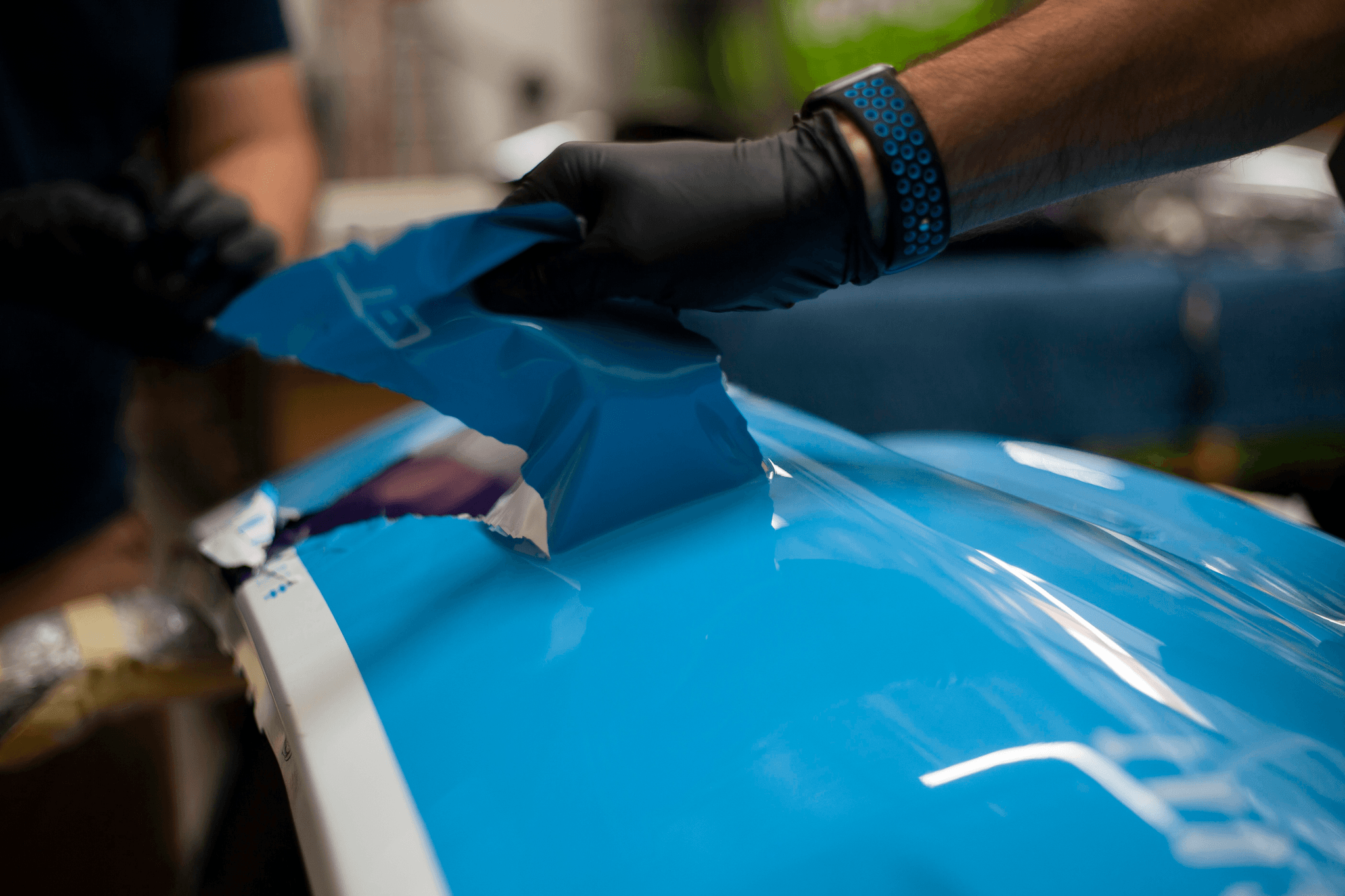

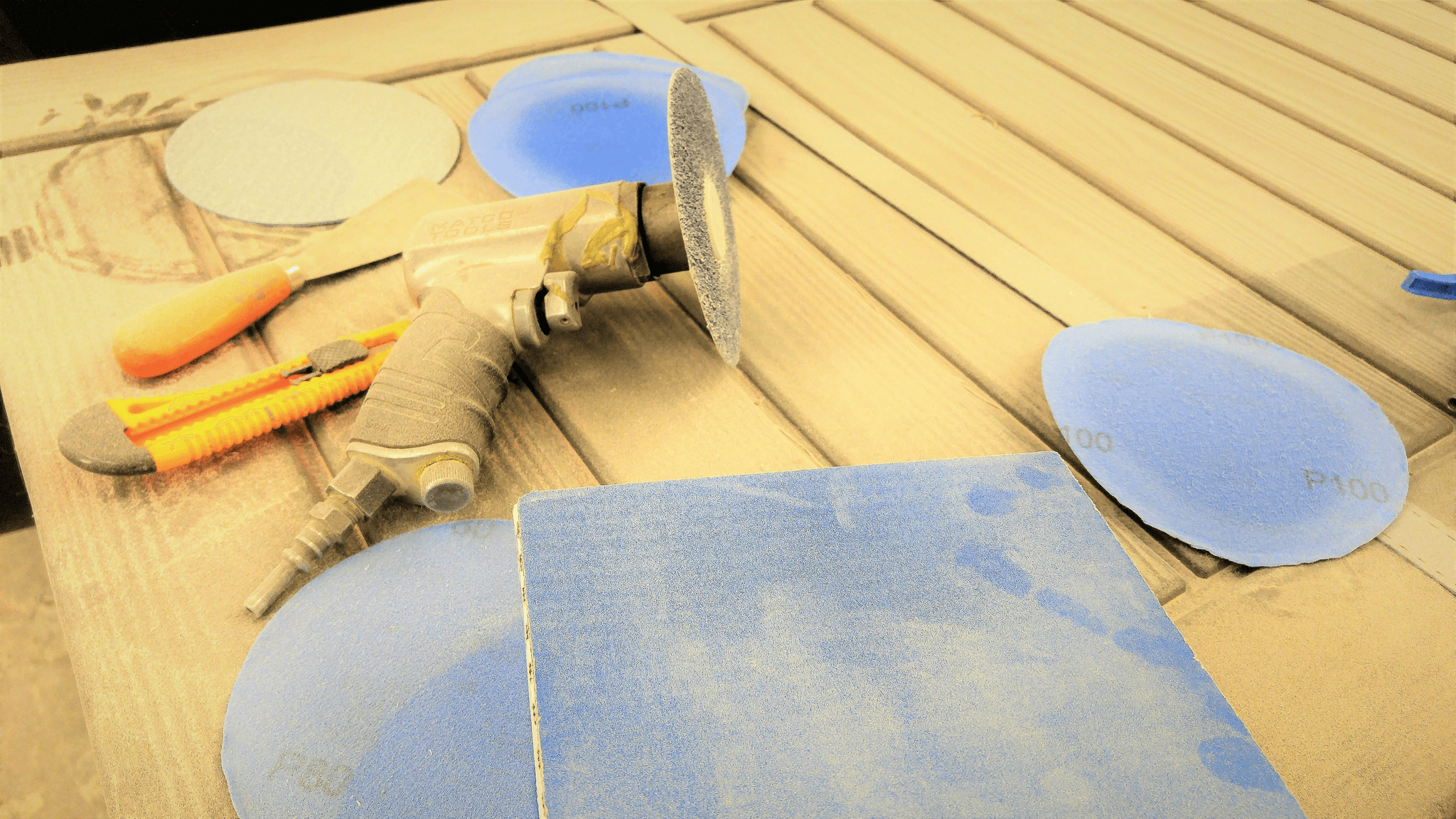

Proper Preparation for Applying Adhesive

When preparing to apply wood adhesive, it is crucial to ensure that the surface is clean and free from any dust, dirt, or grease. This can be achieved by sanding the wood surface and wiping it down with a clean cloth. Additionally, using a primer specifically designed for wood adhesive can help improve adhesion and ensure a strong bond between the wood and glue.

Surface Preparation for Applying Wood Adhesive

Before applying wood adhesive glue, it is important to make sure that the surfaces to be bonded are properly aligned and fit together seamlessly. This will help prevent any gaps or unevenness that could compromise the strength of the bond. Using clamps or weights to hold the pieces in place during curing can also help ensure a tight and secure bond.

It is also important to ensure that the surfaces are clean and free of any dust, debris, or oils that could interfere with the adhesive bond. Properly preparing the surfaces by sanding or using a solvent to remove any contaminants will help maximize the effectiveness of the wood adhesive glue. Additionally, following the manufacturer's instructions for application and curing times is crucial to achieving the strongest and most durable bond possible.

Tips for Ensuring Proper Adhesion on Wood and Plastic Surfaces

When working with both wood and plastic surfaces, it is essential to choose an adhesive that is compatible with both materials. It's important to select a polyurethane adhesive that has been specifically formulated for bonding these two types of surfaces together. Additionally, ensuring that both surfaces are clean, dry, and free from any contaminants will help promote proper adhesion.

When applying the adhesive, it's crucial to follow the manufacturer's instructions carefully to achieve the best results. This may include using a specific application method, allowing for proper curing time, and ensuring that the adhesive is applied evenly across both surfaces. By taking these steps, you can ensure a strong and durable bond between wood and plastic materials for your project.

Advantages of Using Water-Based Resin Solution for Surface Preparation

Using a water-based resin solution for surface preparation offers several advantages when applying adhesive for polyurethane. This type of solution provides excellent adhesion promotion by creating a strong bond between the substrate and the adhesive. It also offers environmental benefits by being non-toxic and having low volatile organic compound (VOC) emissions.

Furthermore, using a water-based resin solution for surface preparation can also improve the overall durability and longevity of the adhesive bond. This type of solution is known for its ability to enhance the performance of polyurethane adhesives, making it an ideal choice for a wide range of applications in various industries. Additionally, the water-based nature of the resin solution makes it easy to clean up and dispose of, further contributing to its environmental friendliness and overall appeal for use in adhesive applications.

Remember that proper preparation is essential when applying adhesive to ensure optimal bonding strength and durability.

Techniques for Applying Adhesive

When applying adhesive to wood surfaces, it's crucial to ensure that the surface is clean and free of any dust or debris that could affect the bond. Using a wood adhesive glue that is specifically designed for porous materials like wood is essential for achieving a strong and durable bond. Apply an even layer of the adhesive to the wood surface, ensuring full coverage before joining the pieces together.

Applying Adhesive to Wood Surfaces

To achieve optimal results when using wood adhesive, it's important to follow the manufacturer's instructions for application and curing times. Additionally, clamping the bonded pieces together can help create a tighter bond and prevent any movement while the adhesive sets. When using wood and glue, it's essential to work in a well-ventilated area and wear protective gear to ensure safety during application.

Best Practices for Applying Polyurethane Adhesive to Plastic

When applying polyurethane adhesive to plastic surfaces, it's important to select an adhesive that is specifically formulated for bonding plastics. Clean the plastic surface thoroughly with a suitable solvent before applying the adhesive, as this will help ensure proper adhesion. Apply the polyurethane glue evenly on the plastic surface and follow the recommended curing time for optimal bonding strength.

How Water-Based Resin Solution Enhances Application Techniques

Using a water-based resin solution in adhesive applications offers several advantages, including improved flow and wetting properties that enhance adhesion on various surfaces. This solution can also improve open time, allowing for easier repositioning of materials during assembly. Additionally, water-based resin solutions are environmentally friendly and contribute to sustainable practices in adhesive usage.

Ensuring Strong and Durable Bond

When it comes to ensuring a strong and durable bond, there are several key factors that can impact the effectiveness of the adhesive. The type of material being bonded, surface preparation, and environmental conditions all play a crucial role in determining the strength of the adhesive bond. For wood adhesive glue and polyurethane glue applications, it is important to consider these factors to achieve optimal results and long-lasting bonds.

Factors Impacting the Strength of Adhesive Bonds

The strength of adhesive bonds can be impacted by various factors such as surface cleanliness, roughness, and porosity. In addition, temperature and humidity levels during application can also affect the curing process and overall bond strength. For wood adhesive applications, ensuring that the wood surfaces are free from dust, oils, and other contaminants is essential for achieving a strong bond. Similarly, for polyurethane adhesive on plastic surfaces, proper cleaning and preparation are crucial for maximizing bond strength.

Enhancing Durability of Adhesive Bonds on Different Materials

To enhance the durability of adhesive bonds on different materials such as wood and plastic, it is important to select an adhesive that is specifically designed for the intended substrate. Wood adhesive should be chosen based on its compatibility with different types of wood species and grain orientations to ensure long-lasting bonds. Similarly, for polyurethane glue applications on plastic materials, selecting an adhesive with excellent adhesion properties tailored to specific plastic substrates is essential for enhancing durability.

The Role of Water-Based Resin Solution in Creating Long Lasting Bonds

Water-based resin solutions play a vital role in creating long-lasting bonds by providing excellent adhesion properties while also offering environmental benefits. These solutions are designed to penetrate into porous substrates such as wood or plastic surfaces, creating a strong interlocking bond that enhances durability over time. Additionally, water-based resin solutions contribute to improved flexibility and resistance to environmental factors such as moisture and temperature changes, further enhancing the longevity of adhesive bonds.

Safety and Environmental Considerations

Importance of Safe Handling and Application of Adhesive

When working with wood adhesive or polyurethane glue, it is crucial to prioritize safety during handling and application. Proper ventilation should be ensured to prevent inhalation of harmful fumes, and protective gear such as gloves and goggles should be worn to avoid skin contact and eye irritation. Additionally, following the manufacturer's guidelines for storage and disposal of adhesive products is essential to minimize potential risks.

Environmental Benefits of Using Water-Based Resin Solution

The use of water-based resin solution as an adhesive for polyurethane offers significant environmental advantages. Unlike solvent-based adhesives, water-based solutions have lower volatile organic compound (VOC) emissions, reducing air pollution and contributing to a healthier indoor environment. Furthermore, the production process for water-based resin solutions typically involves fewer hazardous chemicals, making them a more sustainable choice for environmentally conscious consumers.

Promoting Sustainability Through the Use of Eco-Friendly Adhesives

By choosing eco-friendly adhesives such as water-based resin solutions for wood and plastic applications, individuals can actively contribute to sustainability efforts. These adhesives are formulated with renewable resources and biodegradable components, minimizing their impact on the environment throughout their lifecycle. Embracing eco-friendly options not only supports sustainable practices but also encourages innovation in the development of greener adhesive solutions.

Conclusion

When it comes to achieving optimal results with the right adhesive for polyurethane, it's crucial to consider the specific properties and requirements of the materials involved. By understanding the importance of choosing the right wood adhesive glue and polyurethane glue, you can ensure strong and durable bonds that stand the test of time.

Achieving Optimal Results with the Right Adhesive for Polyurethane

Selecting the appropriate adhesive for polyurethane is essential in ensuring a successful bonding process. Whether it's wood adhesive or adhesive on plastic, taking into account factors such as compatibility, strength, and flexibility will help achieve optimal results. By carefully considering these aspects, you can ensure that your adhesive bonds are reliable and long-lasting.

Advantages of Using Water-Based Resin Solution in Adhesive Applications

The use of water-based resin solution offers numerous advantages when it comes to adhesive applications for polyurethane. Not only does it provide excellent adhesion properties, but it also offers environmental benefits by reducing harmful emissions and promoting sustainability. Additionally, its versatility makes it suitable for a wide range of materials, making it an ideal choice for various bonding needs.

Ensuring Safety, Durability, and Environmental Responsibility in Adhesive Usage

Safety should always be a top priority when handling adhesives, especially when working with polyurethane and other potentially hazardous materials. Additionally, prioritizing durability ensures that adhesive bonds remain strong over time, providing reliable performance in various applications. Furthermore, by choosing eco-friendly options such as water-based resin solutions, you can contribute to environmental responsibility while achieving exceptional bonding results.