Introduction

In the world of adhesives, water-based bonding agents have emerged as a versatile and eco-friendly alternative to traditional options. These innovative bonding glues offer a range of benefits, from reduced toxicity to ease of cleanup, making them increasingly popular in various industries. As environmental consciousness grows, understanding the nuances of water-based bonding adhesives becomes essential for both consumers and professionals alike.

Understanding Water-Based Bonding Adhesives

Water-based bonding adhesives are formulated using water as the primary solvent, which sets them apart from solvent-based counterparts that often contain harmful chemicals. This unique composition not only makes them safer for users but also less damaging to the environment. By leveraging natural ingredients and minimizing volatile organic compounds (VOCs), these adhesives provide a reliable solution for diverse applications while promoting sustainable practices.

The Rise of Eco-Friendly Bonding Solutions

The shift towards eco-friendly bonding solutions has been fueled by increasing awareness of environmental issues and stricter regulations on hazardous materials. Consumers are now more inclined to choose products that align with their values, leading to a surge in demand for water-based bonding agents. This trend reflects a broader movement toward sustainability across various sectors, encouraging manufacturers to innovate and develop greener alternatives without compromising performance.

Key Applications for Bonding Glue

Water-based bonding glue finds its way into numerous applications ranging from woodworking and construction to arts and crafts. Its versatility allows it to bond different materials effectively, including wood, paper, fabric, and certain plastics. As industries continue exploring new possibilities with these adhesives, understanding their specific applications can help users maximize their performance while benefiting from their eco-friendly properties.

Fundamentals of Water-Based Adhesives

Water-based adhesives have become increasingly popular in various industries due to their eco-friendly nature and versatility. These bonding agents utilize water as a solvent, making them less harmful to the environment compared to traditional solvent-based options. Understanding the fundamentals of water-based bonding adhesives is crucial for anyone looking to make informed decisions about their adhesive choices.

What Are Water-Based Bonding Adhesives

Water-based bonding adhesives are formulated primarily with water as the main solvent, allowing for effective adhesion without the harsh chemicals found in many solvent-based products. This type of adhesive is particularly favored in applications where safety and environmental impact are critical considerations, such as in furniture manufacturing and construction. With a wide range of formulations available, these adhesives can bond various materials, including wood, paper, fabric, and even certain plastics.

Key Components and Their Functions

The effectiveness of water-based bonding glue lies in its key components: polymers, fillers, and additives. Polymers provide the primary adhesive properties that enable strong bonds between surfaces; they form a film as the water evaporates during curing. Fillers enhance specific characteristics like viscosity or texture, while additives can improve performance aspects such as drying time or resistance to moisture and heat.

Advantages Over Solvent-Based Options

One major advantage of water-based bonding agents is their lower environmental impact; they emit fewer volatile organic compounds (VOCs), making them safer for indoor use and reducing air pollution concerns. Additionally, these adhesives often offer easier cleanup with just soap and water compared to solvent-based options that require harsher chemicals for removal. Finally, water-based bonding adhesives tend to have superior flexibility once cured, allowing them to accommodate movement without compromising bond strength.

Choosing the Right Bonding Agents

Selecting the right bonding agents is crucial for achieving strong and lasting results with water-based adhesives. With a variety of options available, understanding the different types of bonding glue can help you make informed choices tailored to your specific projects. Whether you're working on crafts, furniture assembly, or industrial applications, knowing which water-based bonding adhesive to use can make all the difference.

Types of Water-Based Bonding Agents

Water-based bonding agents come in several forms, each designed for particular applications and materials. Common types include PVA (polyvinyl acetate) adhesives, which are ideal for porous surfaces like wood and paper, and acrylic emulsions that offer flexibility and durability on a wider range of substrates. Additionally, there are specialty formulations designed for specific tasks—like fabric bonding or heavy-duty construction—ensuring that there's a suitable water-based adhesive for nearly every project.

When choosing your bonding glue, consider its intended use; some agents provide stronger bonds under stress while others excel in providing flexibility or quick drying times. Understanding these distinctions will help you select the best water-based bonding adhesive that meets your needs without compromising quality or performance. Ultimately, selecting the right type can significantly enhance adhesion and durability in your finished products.

Factors to Consider for Optimal Adhesion

First and foremost is surface compatibility; different materials may require specific formulations to achieve maximum bond strength. Additionally, environmental conditions such as temperature and humidity during application can impact how well the adhesive performs.

Another important aspect is curing time; some water-based adhesives set quickly while others may require extended periods to reach their full strength. This factor can influence project timelines significantly—rushing through processes might lead to weaker bonds if not properly accounted for. Lastly, consider any regulatory requirements related to VOC emissions if you're working in sensitive environments—opting for eco-friendly options ensures compliance while also supporting sustainability efforts.

Comparing Chemix's Water-Based Resin Solutions

Chemix offers an impressive lineup of water-based resin solutions tailored for various applications that cater to both DIY enthusiasts and professional users alike. Their products stand out due to their versatility across multiple substrates—including wood, metal, plastic—and their commitment to eco-friendly formulations without sacrificing performance quality when it comes to bonding glue.

One notable option is Chemix’s high-performance acrylic resin adhesive which provides excellent flexibility and resistance against environmental factors like moisture and temperature fluctuations—perfect for outdoor projects! Another highlight is their fast-setting PVA glue that delivers strong bonds on porous surfaces with minimal drying time required—a game-changer when time is of the essence.

In conclusion, comparing Chemix's offerings allows consumers not only access to top-quality products but also peace of mind knowing they’re choosing safe and effective solutions in today’s eco-conscious market landscape—all while ensuring optimal adhesion with their chosen water-based bonding agents.

Surface Preparation Techniques

When it comes to achieving a solid bond with water-based adhesives, surface preparation is the unsung hero of the bonding process. Proper surface prep ensures that your bonding glue adheres effectively, avoiding future mishaps like peeling or separation. Neglecting this crucial step can lead to subpar results, no matter how high-quality your bonding agents are.

Importance of Proper Surface Prep

Proper surface preparation is vital for maximizing the effectiveness of water-based bonding adhesives. Without cleaning and preparing surfaces adequately, contaminants like dust, grease, or old adhesive residue can compromise adhesion. A well-prepped surface creates an ideal environment for your bonding glue to form a strong and lasting bond.

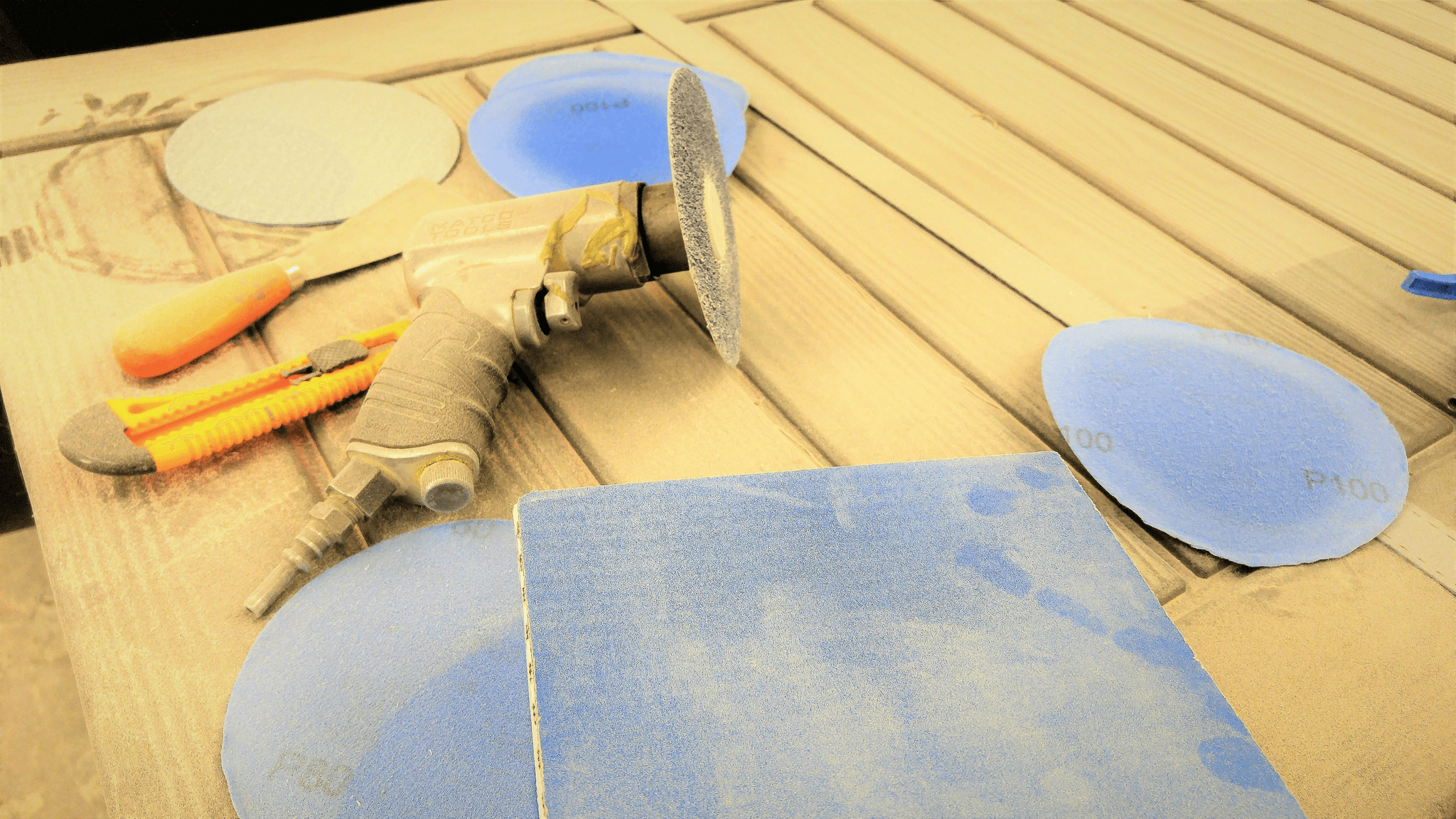

Cleaning, Sanding, and Priming Surfaces

To start the surface preparation process, begin with cleaning—this means removing any dirt or oils that could interfere with the bonding agents' performance. Next comes sanding; this step roughens up smooth surfaces to create more area for the water-based adhesive to grip onto. Finally, priming may be necessary for certain materials; it helps seal porous surfaces and enhances compatibility with your chosen bonding glue.

Testing Surface Compatibility

Before diving headfirst into applying your water-based bonding adhesive, it’s wise to conduct a compatibility test on your surfaces. This involves applying a small amount of adhesive on both materials and allowing it to cure for a short period before assessing adhesion strength. By testing compatibility first, you can avoid potential disasters down the line when using different substrates with your chosen bonding agents.

Application Techniques for Best Results

When it comes to applying bonding glue, the right tools and methods can make all the difference. Water-based adhesives offer a versatile solution for various projects, but their effectiveness largely depends on how well they are applied. Understanding the best practices for application will ensure a strong bond and enhance the overall performance of your chosen bonding agents.

Tools and Methods for Applying Bonding Glue

Selecting the appropriate tools is crucial when working with water-based bonding adhesive. Brushes, rollers, and spray applicators are popular choices; each has its own advantages depending on the surface area and type of project at hand. For small or intricate applications, a fine brush may provide better control, while larger surfaces might benefit from a roller or spray method to achieve an even coat of bonding glue.

Moreover, always consider using disposable tools when working with water-based adhesives to avoid contamination with other substances that could affect adhesion. Clean-up is generally easier with water-based products due to their lower toxicity compared to solvent-based options; however, having dedicated tools can save time and hassle in preparation. Ultimately, choosing the right tool not only makes application smoother but also maximizes the performance of your water-based bonding agents.

Best Practices for Even Coating

Achieving an even coat of bonding glue is vital for ensuring optimal adhesion across surfaces. Start by applying a thin layer of your chosen water-based adhesive using consistent pressure during application—this helps prevent pooling or uneven spots that could compromise bond strength later on. Remember that less is often more; over-applying can lead to longer drying times and potential issues with curing.

Additionally, consider working in sections if you're applying adhesive over large areas; this allows you to focus on achieving uniform coverage without feeling rushed. Regularly check your progress as you go along—it's easier to correct any inconsistencies early rather than after everything has dried! By following these best practices, you'll set yourself up for success when using water-based bonding adhesives.

Tips for Controlling Temperature and Humidity

The environment where you apply your bonding agents plays a significant role in determining how well they perform. Ideally, work in conditions where temperature ranges between 60°F (15°C) and 80°F (27°C) with moderate humidity levels—too much moisture or extreme heat can negatively impact curing times and adhesion quality of your water-based bonding adhesive.

If you're tackling projects outdoors or in unregulated environments, keep an eye on weather forecasts so you can plan accordingly; sudden changes could throw off your carefully laid plans! Additionally, employing fans or dehumidifiers can help maintain ideal conditions if you're working indoors—a little effort here goes a long way toward ensuring strong bonds with minimal issues down the line.

Curing and Finalizing Your Bond

Curing is the process that transforms your water-based bonding adhesive from a liquid into a solid, creating a robust bond between surfaces. Understanding curing times is crucial because it varies depending on the specific bonding agents used, temperature, and humidity levels. Rushing this process can lead to weak bonds that may not hold up under stress, so patience is key here.

Understanding Curing Times for Adhesives

Curing times for water-based adhesives can range from minutes to several hours or even days, depending on the formulation and conditions. It's essential to consult the manufacturer's guidelines for specific curing times associated with your chosen bonding glue; this will ensure optimal performance. Keep in mind that environmental factors like humidity and temperature can significantly influence these times—higher humidity often accelerates curing while lower temperatures may slow it down.

How to Ensure a Strong Final Bond

To achieve a strong final bond using water-based bonding adhesives, proper application techniques are vital. First, ensure that surfaces are clean and prepared correctly; any contaminants can interfere with adhesion and weaken the bond. After applying your bonding glue, allow adequate time for curing without disturbing the assembly—this means no poking or prodding while it's setting!

Additionally, maintaining appropriate conditions during curing can significantly enhance bond strength; aim for stable temperatures and moderate humidity levels throughout this period. If possible, use clamps or weights to hold materials together firmly until full cure is achieved; this helps prevent movement that could jeopardize adhesion.

Troubleshooting Common Adhesive Issues

Even the best-laid plans can go awry when working with bonding agents! Common issues include insufficient adhesion due to improper surface preparation or incorrect application methods—if you notice peeling or separation after curing, revisit your prep steps first. Another frequent problem is bubbling or foaming during application; this could indicate over-application of adhesive or improper mixing if you're using a two-part system.

If you encounter issues like slow curing times or weak bonds despite following guidelines meticulously, consider environmental factors as potential culprits—extreme temperatures or high moisture levels can wreak havoc on even top-quality water-based adhesives. Keep an eye out for these common pitfalls so you can troubleshoot effectively and enjoy lasting results from your chosen bonding glue.

Conclusion

In wrapping up our exploration of water-based adhesives, it’s clear that they represent a significant advancement in the world of bonding solutions. These eco-friendly bonding agents not only provide effective adhesion but also align with the growing demand for sustainable practices in various industries. As we move forward, understanding best practices and innovations in water-based bonding glue will be crucial for maximizing their potential.

Best Practices for Water-Based Adhesive Use

To get the most out of your water-based adhesive, proper application is key. Always ensure surfaces are clean, dry, and free from contaminants before applying your bonding glue; this sets the foundation for a strong bond. Additionally, using the appropriate amount of adhesive can prevent issues like dripping or uneven coating—aim for a thin layer that covers adequately without excess.

Temperature and humidity play significant roles in how well water-based adhesives perform; therefore, monitoring these conditions during application is essential. If you’re working in an environment that’s too cold or humid, consider adjusting your workspace to ensure optimal curing conditions. Lastly, always refer to manufacturer guidelines specific to your chosen bonding agents to avoid common pitfalls.

The Future of Eco-Friendly Bonding Solutions

The future looks bright for eco-friendly bonding solutions as industries increasingly prioritize sustainability without sacrificing performance. Innovations in water-based bonding adhesives are paving the way for more efficient products that meet stringent environmental regulations while providing superior adhesion qualities compared to traditional options. As consumers become more environmentally conscious, companies will likely invest further in developing advanced formulations that minimize harmful emissions.

Moreover, we can expect advancements in technology that enhance the effectiveness of these water-based adhesives across various applications—from construction to crafts and packaging materials. The push towards greener alternatives means we’ll see more research focused on creating versatile bonding agents that cater to diverse needs while being kinder to our planet. This trend will not only benefit manufacturers but also consumers looking for safer choices.

Maximizing Performance with Water-Based Products

To truly maximize performance with water-based products like bonding glue, consider integrating them into a holistic approach involving surface preparation and application techniques discussed earlier. Regularly testing different surfaces can help identify which combinations yield the best results when using specific bonding agents—this trial-and-error process is invaluable for achieving optimal adhesion over time.

Additionally, staying informed about new developments within the realm of water-based adhesives allows users to adapt quickly and leverage cutting-edge solutions as they emerge on the market. By embracing continuous learning and experimentation with these products, users can ensure they’re getting top-notch performance while contributing positively toward sustainable practices.