Introduction

When it comes to bonding aluminum foil to various surfaces, using aluminum foil adhesive is essential for ensuring a strong and durable connection. This specialized adhesive is designed to provide excellent adhesion to aluminum foil, making it a versatile solution for a wide range of applications.

Understanding Aluminum Foil Adhesive

Aluminum foil adhesive is a type of super glue that is specifically formulated to bond aluminum foil to different materials such as metal, glass, and plastic. It offers a strong and long-lasting bond that can withstand various environmental conditions, making it an ideal choice for both indoor and outdoor use.

Benefits of Using Aluminum Foil Adhesive

One of the key benefits of using aluminum foil adhesive is its ability to create a secure and reliable bond between the foil and the substrate. This not only helps in preventing leaks and moisture penetration but also enhances the overall durability of the bonded materials. Additionally, aluminum foil adhesive provides excellent heat resistance, making it suitable for applications that involve high temperatures.

Furthermore, aluminum foil adhesive offers a versatile solution for various industries such as automotive, construction, and packaging. Its ability to adhere to different surfaces including metal, plastic, and glass makes it a go-to choice for manufacturers looking for a reliable bonding solution. With its lightweight and flexible nature, aluminum foil adhesive also provides ease of use and application, making it a cost-effective option for businesses looking to improve their production processes.

Applications of Aluminum Foil Adhesive

The versatility of aluminum foil adhesive makes it suitable for a wide range of applications, including HVAC systems, automotive repairs, insulation installation, and packaging solutions. Its ability to adhere to different surfaces makes it an indispensable tool in various industries where bonding aluminum foil is essential for product performance and longevity.

Now continue with II. Choosing the Right Aluminum Foil Adhesive

Choosing the Right Aluminum Foil Adhesive

When choosing the right aluminum foil adhesive, there are several factors to consider. These include the specific application, the materials being bonded, and the environmental conditions the adhesive will be exposed to. It's important to select an adhesive that offers strong adhesion, durability, and resistance to heat and moisture.

Factors to Consider

Consider the temperature range in which the adhesive will be used, as well as any exposure to chemicals or outdoor elements. It's also important to take into account the flexibility and curing time of the adhesive, ensuring it meets the requirements of your project. Additionally, consider whether a solvent-based or water-based adhesive is more suitable for your needs.

Consider consulting with a materials engineer or adhesive specialist to ensure you select the most appropriate adhesive for your specific application. They can provide valuable insights and recommendations based on their expertise and experience. By seeking professional guidance, you can make an informed decision that will ultimately contribute to the success and longevity of your project.

Comparison of Super Glue, E6000 Adhesive, and Loc Tite

Super glue is known for its fast bonding capabilities but may not provide long-term durability for aluminum foil applications. E6000 adhesive offers a flexible bond with excellent adhesion to various materials but may require longer curing times. Loc Tite provides a strong bond with resistance to moisture and temperature changes but may not be as flexible as other options.

When choosing an adhesive for aluminum foil applications, it's important to consider the specific requirements of the project. For example, if flexibility is a key factor, E6000 adhesive may be the best option despite its longer curing times. On the other hand, if resistance to moisture and temperature changes is crucial, Loc Tite could be the top choice, even if it may not offer as much flexibility as other adhesives. Ultimately, weighing the pros and cons of each adhesive will help determine the best option for your specific aluminum foil application.

Benefits of Using Water-Based Resin Solution

Water-based resin solutions offer numerous benefits when used as an aluminum foil adhesive. They provide a strong bond while being environmentally friendly and safe for indoor use. Additionally, they offer excellent resistance to heat and moisture while maintaining flexibility for long-lasting durability.

Stay tuned for more valuable information on preparing surfaces for aluminum foil adhesive application in section III!

Preparing Surfaces for Aluminum Foil Adhesive

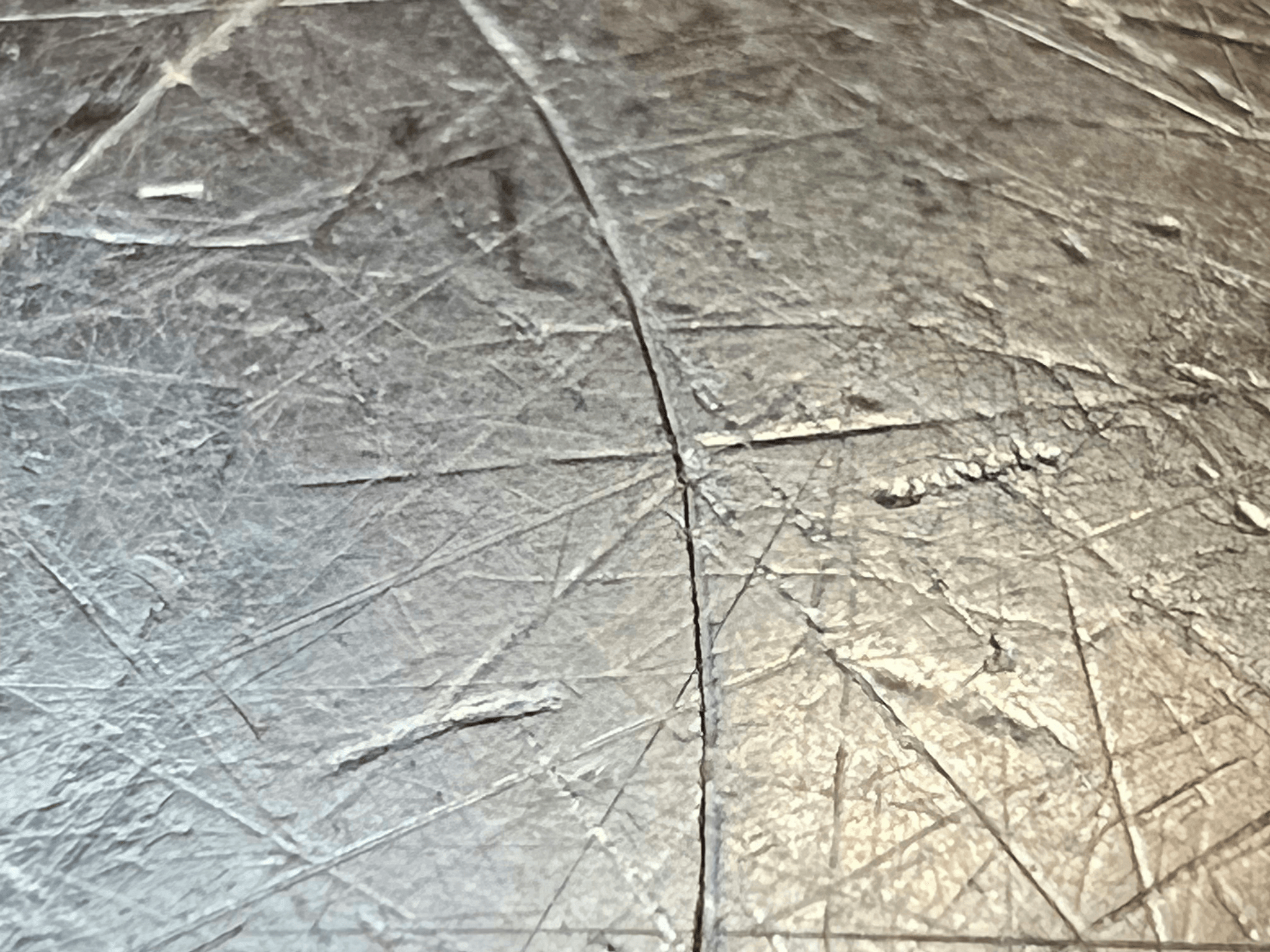

Proper Cleaning Techniques

Before applying aluminum foil adhesive, it is crucial to ensure that the surfaces are clean and free from any dirt, grease, or debris. Use a mild detergent and water to thoroughly clean the surfaces, then dry them completely to promote better adhesion of the adhesive.

Surface Compatibility

It is important to consider the compatibility of the surfaces with the aluminum foil adhesive. Ensure that the materials are suitable for bonding with the adhesive, and take into account factors such as porosity, texture, and temperature resistance to achieve optimal results.

It is also crucial to properly prepare the surfaces before applying the aluminum foil adhesive. Clean the surfaces thoroughly to remove any dirt, dust, or grease that could affect the bonding process. Additionally, roughening or priming the surfaces may be necessary to ensure a strong and durable bond with the adhesive. Taking these steps will help to maximize the effectiveness of the aluminum foil adhesive and ensure long-lasting adhesion between the materials.

Applying Water-Based Resin Solution for Enhanced Adhesion

To further enhance adhesion, consider using a water-based resin solution in conjunction with the aluminum foil adhesive. This solution can help create a stronger bond between the adhesive and the surfaces, providing added durability and longevity to the bond.

One important consideration when using a water-based resin solution is to ensure that the surfaces are clean and free of any debris or contaminants. Proper surface preparation will help maximize the effectiveness of the adhesive and resin solution, resulting in a stronger and more durable bond. Additionally, it is important to follow the manufacturer's instructions for both the adhesive and resin solution to ensure optimal adhesion and long-term performance.

Techniques for Using Aluminum Foil Adhesive

Proper Dispensing and Application

When using aluminum foil adhesive, it is important to dispense the adhesive evenly and apply it in a thin, uniform layer to ensure proper adhesion. Avoid applying too much adhesive as it can lead to messy and inefficient bonding. Use a brush or applicator to evenly spread the adhesive on the surface for best results.

It is also important to allow the adhesive to dry completely before applying the aluminum foil to ensure a strong and durable bond. Follow the manufacturer's instructions for drying time and any additional steps for optimal adhesion. Additionally, make sure the surface is clean and free of any debris or oils that could interfere with the bonding process.

Bonding Methods for Different Materials

Aluminum foil adhesive is versatile and can bond with a variety of materials including glass, wood, plastic, and metal. For non-porous surfaces like glass or metal, apply the adhesive directly onto the surface. For porous materials like wood or plastic, it is recommended to apply the adhesive on both surfaces for a stronger bond.

Enhancing Strength and Durability with Water-Based Resin Solution

To enhance the strength and durability of aluminum foil adhesive bonds, consider using a water-based resin solution as a primer before applying the adhesive. The water-based resin solution acts as a bonding agent that improves adhesion and provides added strength to the bond. This additional step can significantly increase the longevity of your bonded materials.

One important factor to consider when using a water-based resin solution as a primer is the proper application technique. It is crucial to follow the manufacturer's instructions for mixing and applying the primer to ensure maximum effectiveness. Additionally, allowing sufficient drying time for the primer before applying the adhesive is essential for achieving a strong and durable bond.

Troubleshooting Common Issues

Addressing Adhesion Problems

One common issue when using aluminum foil adhesive is poor adhesion, which can result in weak bonds and potential failure of the application. To address this problem, ensure that the surfaces are properly cleaned and prepared before applying the adhesive. Additionally, consider using a water-based resin solution to enhance adhesion and create a stronger bond between the aluminum foil and the substrate.

Dealing with Excess Adhesive

Excess adhesive can be messy and compromise the aesthetics of your project. To deal with this issue, carefully remove any excess adhesive using a solvent or scraping tool before it fully cures. Be sure to follow safety guidelines when handling solvents, and consider using a water-based resin solution for its ease of application and clean-up.

When using a solvent to remove excess adhesive, be sure to work in a well-ventilated area and wear protective gloves to avoid skin irritation. Additionally, consider using a putty knife or scraper tool to gently remove any dried adhesive residue for a smooth and polished finish. Taking these extra steps will ensure that your project looks professional and well-crafted.

Utilizing Water-Based Resin Solution for Seamless Repairs

When faced with repairs involving aluminum foil adhesive, utilizing a water-based resin solution can provide seamless results. This environmentally friendly solution not only enhances adhesion but also allows for easy repositioning of the aluminum foil during repairs. Its low odor and quick drying time make it an ideal choice for achieving professional-looking repairs.

Additionally, the water-based resin solution is highly versatile and can be used for a variety of other adhesive applications, making it a valuable tool to have in any repair kit. Its durability and resistance to moisture and heat ensure that the repaired aluminum foil will maintain its integrity over time, providing long-lasting results that meet professional standards. Whether for household repairs or industrial applications, this environmentally friendly adhesive solution is a reliable choice for achieving seamless and durable repairs.

Conclusion

Maximize the Potential of Aluminum Foil Adhesive

When it comes to maximizing the potential of aluminum foil adhesive, it's essential to understand its versatility and durability. By choosing the right adhesive and preparing surfaces properly, you can ensure a strong and long-lasting bond for various applications.

Enhanced Performance with Water-Based Resin Solution

For enhanced performance, consider using a water-based resin solution in conjunction with aluminum foil adhesive. This environmentally friendly option not only provides superior adhesion but also enhances durability and strength, making it an ideal choice for a wide range of projects.

Environmental Benefits of Using Water-Based Resin Solution

The use of water-based resin solution offers environmental benefits by reducing the impact of harmful chemicals on ecosystems. By opting for this eco-friendly alternative, you can contribute to a more sustainable future while still achieving high-performance results.

With careful consideration and proper application techniques, aluminum foil adhesive combined with water-based resin solution can offer exceptional bonding capabilities while minimizing environmental impact.