Introduction

In the ever-evolving landscape of adhesives, water born aluminum foil adhesive stands out for its unique properties and applications. As industries seek more sustainable solutions, understanding the benefits and functionalities of these adhesives becomes critical. Whether you're asking yourself, What is the best adhesive for aluminum foil? or pondering What does water do to aluminum foil? this guide will provide clarity.

Understanding Water Born Aluminum Foil Adhesive

Water born aluminum foil adhesive is a type of adhesive that utilizes water as a solvent, making it a more eco-friendly choice compared to traditional solvent-based options. This innovative formulation not only reduces harmful emissions but also offers excellent bonding capabilities for various applications. By leveraging the natural properties of water, these adhesives ensure effective adhesion without compromising on performance.

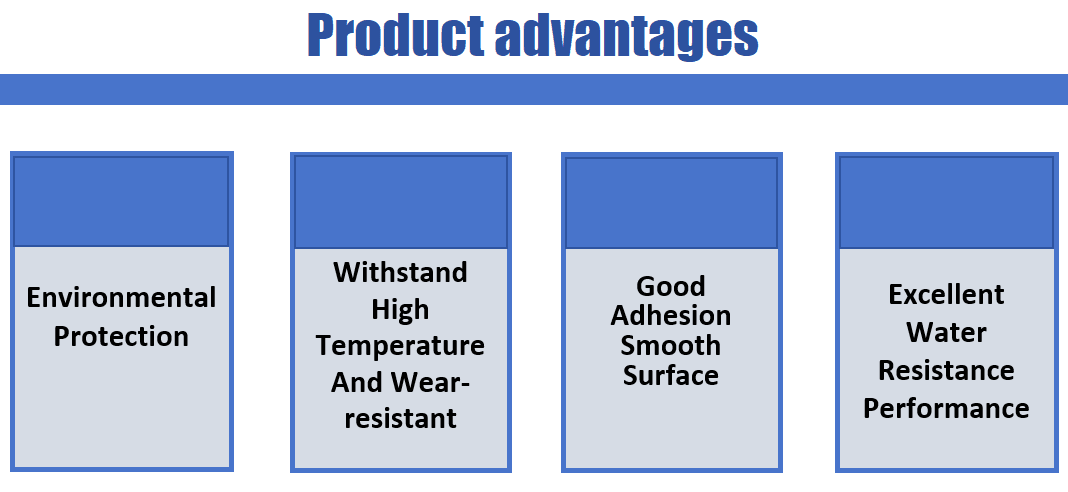

Benefits of Using Water-Based Adhesives

One of the standout advantages of using water-based adhesives is their lower environmental impact, making them an appealing choice for manufacturers looking to go green. Additionally, they typically offer better flexibility and durability once cured, which leads to long-lasting results in various applications. If you’re wondering what glue to use for foil transfer or which glue is best for foil projects, rest assured that water-based options are often at the forefront.

Key Applications for Aluminum Foil Adhesives

Water born aluminum foil adhesives find their way into numerous industries ranging from packaging to automotive manufacturing. Their versatility allows them to be used in everything from food packaging to insulation materials, demonstrating their wide-reaching applicability. With cheap water-borne pressure sensitive adhesive options available on the market, businesses can achieve reliable results without breaking the bank.What is Water Born Aluminum Foil Adhesive?

Water born aluminum foil adhesive is a type of adhesive specifically designed to bond aluminum foil to various surfaces using a water-based solution. Unlike traditional adhesives that rely on solvents, this eco-friendly option utilizes water as its primary carrier, making it safer for both the environment and users. As industries seek sustainable alternatives, water born aluminum foil adhesive has gained traction due to its effectiveness and minimal environmental footprint.

Definition and Composition

At its core, water born aluminum foil adhesive consists of polymer resins dissolved in water, which allows for easy application and quick drying times. This composition not only enhances bonding strength but also reduces harmful emissions commonly associated with solvent-based adhesives. The result is a versatile product that excels in applications where aluminum foil needs to be securely adhered while maintaining safety standards.

How It Differs from Solvent-Based Adhesives

One of the primary differences between water born aluminum foil adhesive and solvent-based adhesives lies in their chemical makeup and curing process. Solvent-based adhesives often contain volatile organic compounds (VOCs) that can release harmful fumes during application, posing health risks to users. In contrast, water-based adhesives are free from these toxic substances, making them the best adhesive for aluminum foil when considering both performance and safety.

Key Benefits of Using Water-Based Adhesives

Choosing water-based adhesives offers several advantages that make them appealing across various industries. Firstly, they are generally easier to clean up compared to their solvent counterparts—just soap and water will do the trick! Additionally, they provide excellent adhesion properties without compromising on flexibility or durability; thus answering the question: What glue to use for foil transfer? Ultimately, opting for cheap water-borne pressure sensitive adhesive solutions not only benefits your projects but also aligns with environmentally conscious practices.

The Science Behind Water Born Aluminum Foil Adhesive

This type of adhesive utilizes water as its primary solvent, which allows for a more eco-friendly approach compared to traditional solvent-based adhesives. The bonding process involves the evaporation of water, leaving behind a strong bond that adheres well to aluminum surfaces, making it an ideal choice for various applications.

How It Bonds and Cures

The bonding mechanism of water born aluminum foil adhesive is fascinating. As the water evaporates, the adhesive forms a film that creates a robust bond with the surface of the aluminum foil. This means that when asking yourself, What is the best adhesive for aluminum foil? look no further than these innovative adhesives—they provide excellent adhesion without compromising on environmental safety.

Moreover, this curing process can be influenced by factors such as temperature and humidity; warmer conditions can accelerate drying times while higher humidity may slow them down. Understanding how these elements affect curing can help you achieve optimal results when using this type of adhesive in your projects.

The Role of Chemix's Water-Based Resin Solution

Chemix's water-based resin solution plays a pivotal role in enhancing the performance of water born aluminum foil adhesive. This unique formulation not only improves adhesion but also contributes to its flexibility and durability over time. If you're wondering what glue to use for foil transfer or which glue is best for foil applications, Chemix’s solution stands out as an excellent choice due to its superior bonding capabilities.

Additionally, this resin solution minimizes harmful emissions typically associated with solvent-based options, making it safer for both users and the environment. By opting for Chemix's innovative technology in your projects, you’re choosing an effective yet eco-conscious approach that aligns with modern sustainability practices.

Environmental Impact and Safety Considerations

One significant advantage of using water born aluminum foil adhesive is its reduced environmental impact compared to traditional adhesives. Since they are primarily composed of water rather than organic solvents, they emit fewer volatile organic compounds (VOCs), leading to better air quality during application and curing processes. This aspect alone makes them an attractive option for anyone concerned about sustainability.

Safety considerations are also paramount; these adhesives are generally non-toxic and pose minimal risk during handling—perfect if you're working on crafts or food packaging where safety standards are crucial. Moreover, if you’re looking into cheap water-borne pressure sensitive adhesives that won’t compromise on quality or safety, consider exploring options within this category.

In summary, understanding the science behind water born aluminum foil adhesive reveals not just how it works but also why it's becoming increasingly popular across various industries—from food packaging to crafting projects—thanks to its environmental benefits and reliable performance.

Application Techniques for Water Born Aluminum Foil Adhesive

Proper techniques ensure that the adhesive performs optimally, providing durability and longevity in various applications. Let’s dive into the best practices for surface preparation, application methods, and tips for achieving that perfect bond strength.

Best Practices for Surface Preparation

Before applying water born aluminum foil adhesive, surface preparation is key to ensuring a successful bond. Start by cleaning the surfaces thoroughly to remove any dust, grease, or contaminants; this step is crucial because even small particles can hinder adhesion. Additionally, roughening smooth surfaces can enhance bonding—consider lightly sanding or using a primer specifically designed for aluminum foil if necessary.

The question often arises: What does water do to aluminum foil? While water itself doesn’t damage aluminum foil, it can affect adhesive performance if not managed correctly during application. Ensuring that surfaces are dry before applying your adhesive will help you avoid potential issues down the line.

Application Methods: Spraying vs. Brushing

When choosing an application method for your water based adhesive, both spraying and brushing have their merits depending on your project’s requirements. Spraying offers even coverage and is particularly effective for large areas or intricate designs where precision is critical; just be sure to use appropriate protective gear to avoid inhaling any misted particles. On the other hand, brushing allows for more control and is ideal when working on smaller projects or detailed work where you want to apply just the right amount of glue.

So what glue should you use for foil transfer? Water born aluminum foil adhesive stands out as an excellent choice due to its versatility and eco-friendliness compared to conventional solvent-based options. The choice between spraying and brushing ultimately depends on your specific needs; both methods can yield impressive results when executed correctly.

Tips for Achieving Optimal Bond Strength

To achieve optimal bond strength with your water based adhesives, timing is everything! Apply the adhesive evenly across both surfaces within the recommended open time specified by the manufacturer—this ensures that you get maximum adhesion before curing begins. Once applied, press both surfaces together firmly; don’t underestimate this step as proper pressure helps create a stronger bond.

If you're wondering which glue is best for foil applications specifically—look no further than our trusty water born aluminum foil adhesive! It not only provides excellent adhesion but also offers flexibility once cured—perfect for applications requiring some movement or flexibility over time. Remember also that environmental factors like temperature and humidity can impact drying times; keep these in mind while working!

Common Uses in Various Industries

Water born aluminum foil adhesive is gaining traction across multiple sectors due to its versatility and eco-friendliness. This adhesive not only meets stringent safety standards but also provides reliable bonding solutions for various applications. Let’s delve into some of the common uses of this innovative adhesive.

Food Packaging and Safety Standards

In the realm of food packaging, safety is paramount, making water born aluminum foil adhesive an ideal choice. Its non-toxic composition ensures that no harmful chemicals leach into food products, adhering to rigorous safety standards set by regulatory bodies. As consumers become more health-conscious, the demand for adhesives that are both effective and safe continues to rise—making this eco-friendly option a top contender.

Additionally, these adhesives withstand various environmental factors such as moisture and temperature fluctuations, ensuring that packaged goods remain intact during transportation and storage. For those in the food industry looking for a reliable solution, water born aluminum foil adhesive checks all the boxes.

Automotive and Aerospace Applications

The automotive and aerospace industries have long relied on advanced materials that require specialized adhesives for optimal performance. Water born aluminum foil adhesive offers excellent adhesion properties while minimizing environmental impact—traits that are crucial in these high-stakes fields. The lightweight nature of aluminum combined with this type of adhesive enhances fuel efficiency without sacrificing structural integrity.

In these sectors, questions like What does water do to aluminum foil? often arise when considering different bonding methods; however, with water-based solutions like this one, moisture actually aids in achieving superior bond strength during curing processes. Furthermore, using a cheap water-borne pressure sensitive adhesive can provide cost-effective solutions without compromising quality or performance under extreme conditions. The versatility of water born aluminum foil adhesive makes it suitable for applications ranging from interior components to critical structural elements.

Textiles and Crafting Projects

Water born aluminum foil adhesive has found its niche within textiles and crafting projects as well—offering creative enthusiasts a reliable bonding agent that’s easy to work with. Whether you’re looking to add metallic accents or create unique designs on fabric surfaces, this type of glue is incredibly versatile and user-friendly. Many crafters often ask which glue is best for foil; with its strong adhesion properties specifically designed for metal surfaces, water based options stand out among competitors.

Additionally, incorporating this type of adhesive into crafting allows artists to explore new techniques such as foil transfer—a process where heat-sensitive foils are applied using specialized glues like our featured product here. This opens up endless possibilities in fashion design or home décor projects where metallic finishes are desired without toxic fumes or messy clean-up associated with solvent-based alternatives. As more people embrace sustainable crafting practices, embracing water born aluminum foil adhesive becomes an appealing choice.

Troubleshooting and Maintenance Tips

Whether you're working on a craft project or in an industrial setting, understanding what can go wrong is key. Let’s dive into some of the most frequent adhesive dilemmas and how to tackle them effectively.

Identifying Common Adhesive Issues

One of the primary concerns with water born aluminum foil adhesive is poor bonding, which can occur for several reasons. If you find that your aluminum foil isn't adhering well, it could be due to inadequate surface preparation or contamination on the surfaces being bonded. Additionally, if you're wondering what glue to use for foil transfer, remember that not all adhesives are created equal; some may not provide the desired strength or durability.

Another common issue is bubbling or wrinkling in the adhesive layer. This often happens when too much moisture is introduced during application—something you might be curious about if you've ever asked, What does water do to aluminum foil? The answer: excessive moisture can weaken the bond and create imperfections in your finished product. Monitoring your application technique will help prevent these problems from arising.

Lastly, improper curing can lead to weak bonds as well. Ensure that you allow sufficient time for your water-based adhesive to set properly before subjecting it to stress or environmental factors; this is particularly crucial if you're using a cheap water-borne pressure-sensitive adhesive that may require more attention during curing.

How to Properly Store and Handle Adhesives

Proper storage of your water born aluminum foil adhesive is essential for maintaining its effectiveness over time. Always keep your adhesives in a cool, dry place away from direct sunlight; exposure to heat can degrade their quality significantly. Additionally, ensure that containers are tightly sealed after each use—this prevents evaporation of moisture which could affect performance.

When handling these adhesives, it's important to follow safety precautions such as wearing gloves and masks when necessary. Water-based adhesives tend to have fewer volatile organic compounds (VOCs), but they still require careful handling especially when transferring them into smaller containers for specific applications like crafting projects where precision matters.

If you're looking for ways on how best to manage leftover adhesive after a project, consider transferring it into smaller jars labeled with dates; this way you’ll know how fresh they are when you’re ready for another round of crafting fun!

Preventing Adhesive Failures

Preventing failures with water born aluminum foil adhesive often comes down to preparation and application techniques. Start by ensuring surfaces are clean—dirt, grease, or dust can ruin even the best glue's chances at success! If you're unsure about which glue is best for foil applications specifically related to food packaging or crafts, opt for high-quality options designed explicitly for those purposes.

Additionally, temperature plays a significant role in achieving optimal bond strength; try applying your adhesives within recommended temperature ranges (generally between 50°F - 90°F). Too cold? The bond may not set properly; too hot? You risk premature drying before proper adhesion occurs!

Finally, always conduct tests before committing large quantities of materials together—especially if you're using new brands or types of adhesives! A simple test piece allows you insight into potential issues without risking valuable materials down the line.

Conclusion

In a world increasingly focused on sustainability, water born aluminum foil adhesive emerges as a champion for eco-friendly bonding solutions. This innovative adhesive not only meets the demands of various industries but also prioritizes environmental safety. By choosing this type of adhesive, users can enjoy strong bonds without compromising their commitment to reducing harmful chemicals.

Why Choose Water Born Aluminum Foil Adhesive

When it comes to selecting an adhesive for aluminum foil, many wonder: what is the best adhesive for aluminum foil? Water born aluminum foil adhesive stands out as a top choice due to its excellent bonding properties and ease of use. Plus, its water-based formulation means it’s less toxic and better for the environment compared to traditional solvent-based options.

Another question that often arises is: what does water do to aluminum foil? In the case of water born adhesives, it acts as a carrier that helps distribute the bonding agents evenly across surfaces, ensuring a strong hold once cured. Users will find that this type of adhesive not only works well for standard applications but also excels in specialized tasks like foil transfer projects—making it versatile enough for any crafting enthusiast.

For those seeking cost-effective solutions, cheap water-borne pressure sensitive adhesives are also available. However, investing in high-quality water born aluminum foil adhesive ensures durability and reliability in your projects. Ultimately, making this choice leads to long-lasting results and peace of mind knowing you're using an eco-friendly product.

Future Trends in Adhesive Technology

As we look ahead, future trends in adhesive technology suggest an increasing shift towards sustainable materials like water-based adhesives. Innovations continue to emerge that enhance performance while minimizing environmental impact—think bio-based formulations or even smart adhesives with self-healing properties! The demand for eco-friendly options is driving research into new technologies that promise improved adhesion without harmful side effects.

Moreover, industries are beginning to recognize the value of adopting these advanced materials not just from an ecological standpoint but also from a performance perspective. For example, manufacturers are exploring how water based adhesives can be optimized further for specific applications such as automotive or aerospace uses where strength and safety are paramount. This evolution will likely lead us toward more efficient production processes that align with global sustainability goals.

As consumers become more environmentally conscious, they will increasingly favor products made with sustainable materials like water born aluminum foil adhesive over traditional alternatives. The future looks bright for those who embrace these changes early on—positioning themselves at the forefront of innovation while contributing positively to our planet's health.

Making the Switch to Eco-Friendly Options

Transitioning from conventional adhesives to eco-friendly options like water born aluminum foil adhesive may seem daunting at first—but it's easier than you think! Start by evaluating your current projects and identifying where you can implement these sustainable alternatives effectively without sacrificing quality or performance. Many users report satisfaction with their results after switching; they appreciate both the environmental benefits and improved working conditions due to reduced fumes and toxicity levels associated with traditional solvents.

It's essential also to educate yourself about which glue is best for foil applications or which glue works best specifically for your needs—this knowledge empowers you when making purchasing decisions moving forward! As more manufacturers embrace greener practices within their operations too; consumers will find plenty of choices available on store shelves soon enough.

Ultimately, making informed decisions about which adhesives we use has far-reaching implications—not just within our own projects but across entire industries striving toward sustainability goals together! So why not take that leap today? Embrace eco-friendly options like water based adhesives; after all—it’s time we all do our part!