Introduction

Understanding Water Soluble Adhesives

Water soluble adhesives are a type of adhesive that utilizes water as a solvent, allowing them to bond materials effectively while minimizing environmental impact. What are water-based adhesives? They typically consist of polymers that dissolve in water, creating a strong bond once dried. This unique formulation not only makes them easy to clean up but also reduces harmful emissions compared to traditional solvent-based adhesives.

Importance of Adhesives for Aluminum Foil

Adhesives play a crucial role in the packaging industry, particularly with aluminum foil products that require secure sealing and durability. The use of water soluble adhesives ensures that the final product is not only effective but also safe for food contact applications. With their quick-drying properties and strong adhesion capabilities, these adhesives enhance the functionality of aluminum foil in various commercial settings.

Common Uses of Water-Based Adhesives

Water-based adhesives have found their place in numerous industries due to their adaptability and effectiveness. From crafting projects using Water Soluble Glue for Fabric to industrial applications requiring robust bonding solutions, these adhesives cater to diverse needs. Additionally, leading water-based adhesive manufacturers are constantly innovating to expand their offerings and improve performance across different sectors.

What Are Water-Based Adhesives?

Water-based adhesives, often referred to as water soluble adhesives, are a type of adhesive that uses water as a primary solvent. These adhesives consist of polymer emulsions or dispersions that provide strong bonding capabilities while being environmentally friendly. The versatility and ease of use make them popular choices in various applications across industries.

Definition and Characteristics

Water-based adhesives are formulated using natural or synthetic polymers that dissolve in water, allowing for easy application and cleanup. Their characteristics include low volatile organic compounds (VOCs), quick drying times, and excellent adhesion to a variety of substrates, including paper, fabric, and even metal surfaces like aluminum foil. Additionally, these adhesives can be designed to be either permanent or temporary based on the specific requirements of the project.

Advantages Over Traditional Adhesives

One significant advantage of water-based adhesives is their lower environmental impact compared to traditional solvent-based options. They emit fewer harmful fumes during application and curing processes, making them safer for both users and the environment. Moreover, water soluble adhesives generally offer superior flexibility after drying, which is beneficial for applications requiring movement without compromising bond strength.

Common Applications

Water-based adhesives find their way into numerous applications across diverse industries due to their adaptability. They are widely used in packaging materials, bookbinding, woodworking, textiles (including Water Soluble Glue for Fabric), and even automotive sectors for bonding components together. Additionally, leading water-based adhesive manufacturers have developed specialized formulations tailored for specific tasks such as laminating or coating surfaces.

How Do Water-Based Adhesives Work?

Water-based adhesives, often referred to as water soluble adhesives, operate through a fascinating interplay of chemistry and physics. Understanding how these adhesives work is crucial for anyone looking to harness their benefits effectively. By delving into the science behind adhesion, we can appreciate why water-based adhesives are favored in various applications.

The Science Behind Adhesion

At its core, adhesion is the process by which two surfaces bond together. Water-based adhesives achieve this through a combination of mechanical interlocking and chemical bonding at the molecular level. When applied, these water soluble adhesives spread across surfaces, allowing for intimate contact that enhances adhesion strength—essentially making them a go-to choice in scenarios where traditional methods might falter.

Role of Water in Adhesive Properties

Water plays a pivotal role in the functionality of water-based adhesives. It acts as both a solvent and a carrier for adhesive components, facilitating their application and ensuring even distribution across surfaces. As the water evaporates during the curing process, it leaves behind a robust adhesive film that provides excellent bonding capabilities without compromising flexibility or durability.

Key Ingredients of Water Soluble Adhesives

Water soluble adhesives typically contain several key ingredients that contribute to their effectiveness. These include polymers that provide elasticity and strength, along with additives that enhance performance characteristics like drying time and viscosity. By understanding what are water based adhesives made from, users can make informed decisions about which products best meet their needs—especially when considering options like Water Soluble Glue for Fabric.

Leading Water-Based Adhesive Manufacturers

The market for water-based adhesives is thriving, with numerous manufacturers stepping up to meet the growing demand for eco-friendly bonding solutions. These companies specialize in developing innovative water soluble adhesives that cater to various industries, including packaging, textiles, and construction. Understanding the top brands can help users make informed choices when selecting the right adhesive for their needs.

Innovations in Water Soluble Adhesives

Innovation is at the forefront of the development of water soluble adhesives, with many manufacturers investing heavily in research and development. Recent advancements focus on enhancing adhesion properties while maintaining environmental sustainability—an increasingly important factor in today's market. From improved formulations that boost performance to new application techniques that simplify usage, these innovations are transforming how we think about adhesives.

Comparing Product Offerings

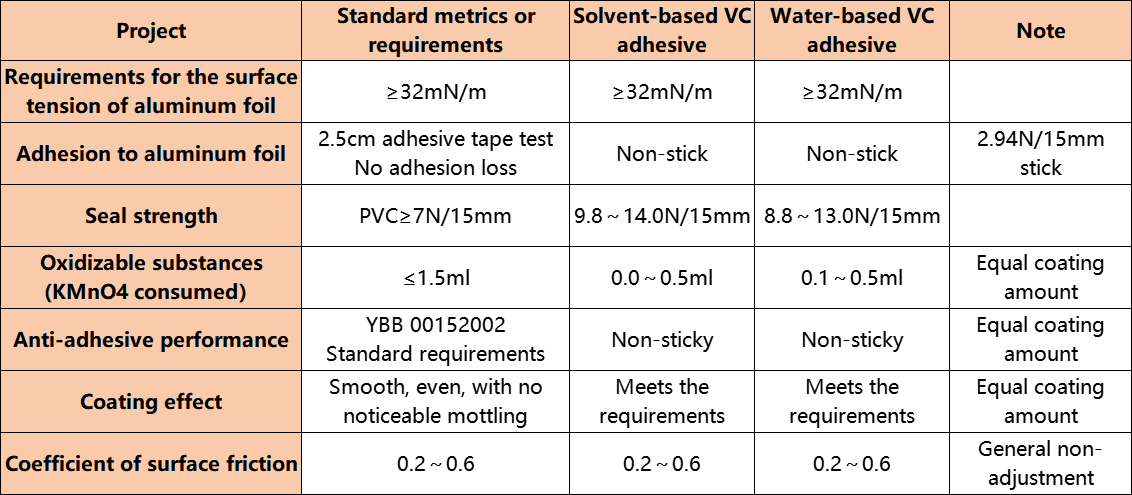

When comparing product offerings from leading water-based adhesive manufacturers, it's essential to consider factors such as performance metrics and application versatility. Some brands excel in providing specialized formulas for unique uses like Water Soluble Glue for Fabric or heavy-duty industrial applications, while others focus on general-purpose solutions suitable for various materials. By evaluating these aspects alongside customer reviews and technical support options, users can select the best adhesive tailored to their specific needs.

Chemix's Water-Based Resin Solution

Chemix has carved a niche in the world of water soluble adhesives with its innovative resin solutions. These resins offer a unique combination of performance and versatility, making them an ideal choice for various applications. With a strong focus on quality and sustainability, Chemix's water-based adhesives are designed to meet the needs of modern industries while minimizing environmental impact.

Benefits of Using Chemix Resins

One of the standout benefits of Chemix resins is their exceptional adhesion properties, which allow them to bond effectively to numerous substrates, including metals and fabrics. These water-based adhesives dry quickly, providing efficient production timelines without compromising on strength or durability. Additionally, Chemix resins are non-toxic and safe for use in environments where health considerations are paramount—making them a smart choice for both manufacturers and end-users.

Applications Across Different Industries

The versatility of Chemix's water soluble adhesives makes them suitable for a wide range of applications across multiple industries. In textiles, they serve as excellent Water Soluble Glue for Fabric, ensuring strong bonds that withstand washing and wear. Beyond textiles, these resins find utility in packaging, woodworking, automotive components, and even electronics—demonstrating how adaptable water-based adhesives can be in real-world scenarios.

Sustainable Practices in Adhesive Production

Sustainability is at the heart of Chemix's operations; they prioritize eco-friendly practices throughout their adhesive production process. By using renewable resources and minimizing waste during manufacturing, Chemix ensures that their water-based adhesives contribute positively to environmental conservation efforts. This commitment not only appeals to environmentally conscious consumers but also positions Chemix as a leader among water based adhesive manufacturers focused on sustainable innovation.

Conclusion

As we wrap up our exploration of water-based adhesives, it’s clear that these innovative solutions are paving the way for a more sustainable future. The versatility and efficacy of water soluble adhesives make them an attractive choice across various industries. With ongoing advancements in formulation and application, the potential for these adhesives is only set to grow.

The Future of Water-Based Adhesives

The future of water-based adhesives looks promising as manufacturers continue to innovate and refine their products. With increasing emphasis on eco-friendly materials, water soluble adhesives are becoming the go-to option for many businesses seeking sustainable alternatives. As technology advances, we can expect even more efficient formulations that enhance adhesion properties while minimizing environmental impact.

Choosing the Right Adhesive for Your Needs

When it comes to selecting the right adhesive, understanding your specific requirements is crucial. Water-based adhesive manufacturers offer a wide range of products tailored to various applications, from packaging to textiles and beyond. By considering factors such as substrate compatibility, drying time, and bond strength, you can ensure optimal performance with your chosen water soluble glue for fabric or other uses.

Maximizing Performance with Water Soluble Adhesives

To maximize performance when using water soluble adhesives, proper application techniques are key. Ensure surfaces are clean and dry before applying the adhesive; this simple step can significantly enhance adhesion strength. Additionally, following manufacturer guidelines regarding curing times and conditions will help you achieve a robust bond that stands the test of time.