Introduction

Hot melt adhesives have become a cornerstone in various industries, offering a versatile solution for bonding materials efficiently and effectively. But what is hot melt adhesive, you may ask? Essentially, it's a thermoplastic adhesive that is applied in a molten state and solidifies upon cooling, creating strong bonds that can withstand various conditions. This introduction will explore the applications of hot melt adhesives across different sectors, the materials they are made from, and the myriad advantages they bring to the table.

Understanding the Basics of Hot Melt Adhesives

At its core, hot melt adhesive is all about simplicity and functionality. These adhesives are typically composed of polymers that provide excellent adhesion properties when heated and then cooled down to form a solid bond. The fascinating aspect of hot melt glue is its ability to be re-melted; this characteristic allows for easy adjustments during application or repair processes.

Applications of Hot Melt Adhesives in Industries

When it comes to industrial usage, you might wonder: what is industrial hot melt adhesive used for? The answer spans across numerous fields including packaging, automotive manufacturing, construction, and even healthcare. From securing labels on products to assembling components in vehicles or medical devices, these adhesives play an essential role in ensuring durability and reliability.

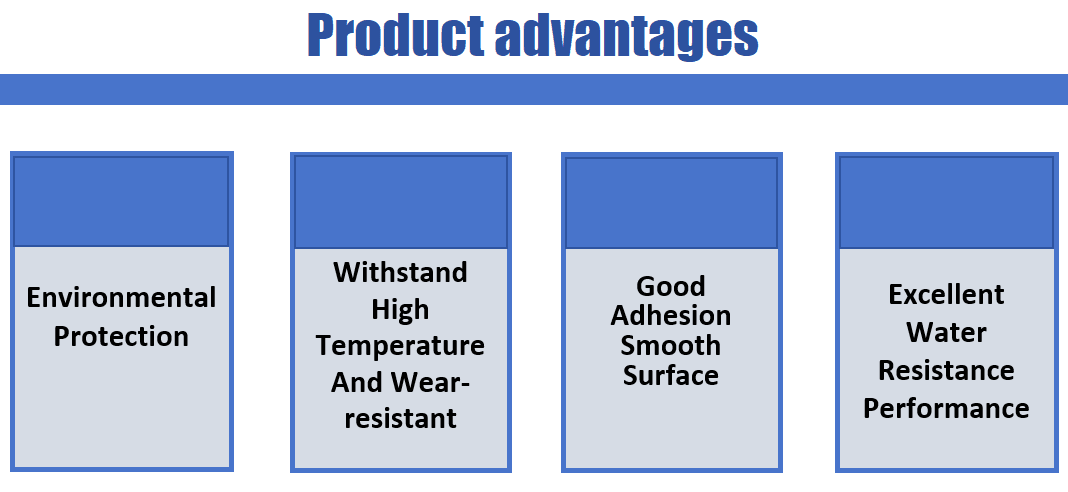

Advantages of Using Hot Melt Adhesives

The advantages of using hot melt adhesives are plentiful and compelling. For starters, they offer quick setting times which enhance productivity—an invaluable trait in fast-paced manufacturing environments. Additionally, their versatility means they can bond a wide range of materials including plastics, metals, and paper products without compromising strength or durability.

What is a Hot Melt Adhesive?

Hot melt adhesives are fascinating materials that have carved out a niche in various industries due to their unique properties and versatility. So, what is hot melt adhesive? Essentially, it is a thermoplastic adhesive that becomes liquid when heated and solidifies upon cooling, creating a strong bond. The instant bonding capability makes hot melt adhesives an attractive option for manufacturers looking for efficient production processes.

Definition and Characteristics

When we talk about the characteristics of hot melt adhesives, we're diving into their defining features: they are typically solvent-free, quick-setting, and can bond a wide range of substrates. One key aspect is their ability to be re-melted; this means that if the bond needs to be adjusted or removed, the adhesive can be reheated without losing its effectiveness. This unique property contributes significantly to answering the question: what is industrial hot melt adhesive used for? Its applications span from packaging to automotive assembly.

The performance of hot melt adhesives also hinges on their composition—often made from polymers like EVA (ethylene-vinyl acetate) or polyolefins—which dictate factors such as flexibility, strength, and temperature resistance. These characteristics make them suitable for both high-speed production environments and more delicate applications where precision is paramount.

Types of Hot Melt Adhesives

Diving deeper into the world of hot melts reveals several types tailored to different applications. The most common types include EVA-based adhesives known for their versatility in packaging and woodworking; polyamide-based adhesives favored in automotive applications due to their heat resistance; and polyurethane-based options that excel in demanding environments requiring flexibility and durability.

Each type serves specific needs based on factors like temperature range, bonding speed, and substrate compatibility. Understanding these variances helps manufacturers choose the right solution when pondering what is industrial hot melt adhesive made of or how it fits into their production line.

Additionally, there are specialty formulations designed for niche markets—think medical-grade adhesives used in healthcare settings or environmentally friendly options aimed at sustainability-conscious companies. This diversity allows businesses across sectors to leverage hot melts effectively while maximizing performance.

Chemix's Hot-melt Resin Overview

Chemix offers an impressive lineup of hot-melt resins designed to meet various industrial needs while ensuring quality performance across diverse applications. Their products exemplify what modern industrial hot melt adhesive should embody—reliability, efficiency, and adaptability—making them ideal for answering questions about how does hot melt glue work in real-world scenarios.

With formulations tailored specifically for high-speed production lines or complex assembly tasks, Chemix’s resins provide excellent adhesion properties without compromising on ease of use or safety standards. Whether you’re working with paper products or intricate electronic assemblies, Chemix has engineered solutions that stand up to rigorous demands while maintaining user-friendly application processes.

In summary, understanding Chemix's offerings not only clarifies what industrial hot melt adhesive is but also underscores its significance in enhancing productivity across various sectors—from packaging innovations to automotive advancements—all while ensuring strong bonds that last.

What is Industrial Hot Melt Adhesive Made Of?

Industrial hot melt adhesives are fascinating materials that combine various raw ingredients to create a strong bonding solution. Understanding what industrial hot melt adhesive is made of can help industries choose the right product for their specific needs. The combination of these materials contributes to the adhesive's performance, durability, and versatility in various applications.

Common Raw Materials Used

The backbone of industrial hot melt adhesives consists of thermoplastic polymers, which are crucial for their adhesive properties. Commonly used polymers include ethylene-vinyl acetate (EVA), polyamide, and polyurethane, each offering unique characteristics suited for different applications. Additionally, fillers and additives such as waxes and stabilizers play essential roles in enhancing performance and processing capabilities.

Chemical Composition and Properties

When we ask, What is industrial hot melt adhesive made of? we delve into its chemical composition that determines its functionality. The primary components—polymers—are responsible for the adhesive’s strength, flexibility, and thermal stability. Furthermore, the balance between these elements influences properties like viscosity during application, curing speed upon cooling, and overall adhesion strength once set.

Importance of Quality in Production

Quality control in the production of industrial hot melt adhesives cannot be overstated; it directly impacts their effectiveness in real-world applications. Variations in raw material quality can lead to inconsistencies in bonding performance or even failure under stress. Therefore, manufacturers must adhere to strict standards to ensure that every batch meets the required specifications for durability and reliability.

What is Industrial Hot Melt Adhesive Used For?

Industrial hot melt adhesives are versatile bonding agents utilized across a myriad of sectors. Their ability to bond quickly and effectively makes them essential in manufacturing, packaging, automotive, and healthcare industries. Understanding what industrial hot melt adhesive is used for can help businesses decide how to incorporate these adhesives into their production processes.

Key Applications in Various Industries

When we ask, What is industrial hot melt adhesive used for? the answer spans multiple applications. In the packaging industry, these adhesives are crucial for securing boxes and cartons swiftly during production lines. The automotive sector also benefits from hot melt adhesives for assembling components due to their strong bonding capabilities and resistance to various environmental factors.

In healthcare, hot melts are employed in medical device assembly and packaging sterile products, ensuring safety and reliability. Additionally, consumer goods manufacturers use these adhesives extensively for product assembly and labeling due to their quick setting time. This wide range of applications demonstrates the adaptability of industrial hot melt adhesives across different fields.

Innovations in Hot Melt Adhesive Usage

The world of industrial hot melt adhesive usage is constantly evolving with innovative techniques that enhance performance and efficiency. Recent advancements include the development of temperature-sensitive formulations that allow for better control over bonding conditions—this means you can apply them at lower temperatures without sacrificing strength or durability.

Moreover, eco-friendly formulations have emerged as a response to environmental concerns; these alternatives maintain performance while reducing harmful emissions during production and application processes. As industries continue to explore new uses for what is hot melt adhesive technology, we can expect ongoing innovation that addresses both performance needs and sustainability goals.

Comparison with Other Adhesive Types

When considering What is industrial hot melt adhesive made of? it’s essential to compare it with other types of adhesives like epoxy or cyanoacrylate (super glue). Unlike epoxy that requires curing time under specific conditions, hot melts bond quickly upon cooling after application—this speed can significantly boost productivity on assembly lines.

Additionally, while traditional solvent-based adhesives may emit volatile organic compounds (VOCs), many modern hot melts offer low-VOC options that make them safer for workers and the environment alike. When weighing your options on adhesive types, remember that each has its strengths; however, the versatility of industrial hot melt adhesives often provides a unique blend of speed, strength, and safety not easily matched by other types.

How Does Hot Melt Glue Work?

Hot melt glue, often referred to as hot melt adhesive, operates on a straightforward yet fascinating principle. When heated, these adhesives become liquid and can be easily applied to various surfaces. Upon cooling, they solidify quickly, forming a strong bond that is both durable and reliable.

The Science Behind Hot Melt Adhesives

What is hot melt adhesive? At its core, it's a thermoplastic material that transitions from solid to liquid when heated and then back to solid upon cooling. This unique property allows for quick application and setting times, making it ideal for numerous industrial applications. The science behind hot melt adhesives involves understanding their polymer structure; they are typically composed of polymers like ethylene-vinyl acetate (EVA) or polyamide that provide flexibility and strength once cured.

Application Techniques and Equipment

When considering what is industrial hot melt adhesive used for, the answer lies in its diverse application techniques. Equipment such as hot glue guns, bulk melters, or spray systems allow users to apply the adhesive efficiently across various materials. Whether bonding cardboard in packaging or assembling components in automotive manufacturing, the right technique ensures optimal performance from your hot melt adhesive.

Curing Process and Bonding Strength

The curing process of hot melt adhesives is relatively rapid compared to other types of adhesives; this speed is one reason why many industries prefer them. Once applied, the cooling phase begins almost immediately as the adhesive transitions back into a solid state—this process creates strong bonding strength between surfaces. Understanding how does hot melt glue work helps manufacturers choose the appropriate type based on their specific needs while ensuring maximum efficiency in production processes.

Hot Melt Adhesive Uses

Hot melt adhesives are versatile materials that find applications across various industries, showcasing their adaptability and effectiveness. From consumer products to healthcare solutions, understanding what is hot melt adhesive and its uses can help businesses streamline their processes and improve product quality. This section delves into the primary applications of hot melt adhesives, demonstrating why they are a go-to choice for many manufacturers.

Consumer Products and Packaging

When it comes to consumer products, hot melt adhesives play a pivotal role in packaging solutions. These adhesives provide quick bonding capabilities that are essential for high-speed production lines, ensuring that items are securely packaged without delay. What is industrial hot melt adhesive used for in this context? Primarily, it's about enhancing efficiency while maintaining a strong bond between materials like cardboard, plastic, and paper.

In addition to packaging, hot melt adhesives are frequently used in crafting consumer goods such as toys and electronics. The ease of application allows manufacturers to create durable products that withstand everyday wear and tear. Furthermore, these adhesives can be formulated to meet specific safety standards required for children's toys or electronic devices.

Automotive and Construction Applications

The automotive industry relies heavily on what is industrial hot melt adhesive made of—namely robust formulations that can withstand extreme conditions. These adhesives are utilized in assembling components such as dashboards, door panels, and headliners where traditional fasteners may not suffice. Their ability to bond dissimilar materials makes them invaluable in modern vehicle manufacturing.

In construction applications, hot melt adhesives offer efficient solutions for flooring installations and insulation projects. The quick setting time allows builders to adhere materials rapidly without compromising structural integrity or aesthetics. As the industry evolves toward more sustainable practices, the demand for eco-friendly hot melt options continues to rise.

Healthcare Industry and Specialized Uses

In the healthcare sector, understanding how does hot melt glue work can significantly influence product development—from medical devices to packaging for pharmaceuticals. Hot melts provide sterile bonding solutions essential for surgical instruments or disposable medical supplies where hygiene is paramount. Their ability to form strong bonds quickly ensures that critical equipment remains intact during use.

Moreover, specialized applications include wound care products where skin-safe formulations are necessary for patient comfort and safety. The versatility of what is industrial hot melt adhesive used for extends into creating custom solutions tailored specifically for healthcare needs—demonstrating its importance beyond traditional uses found in other industries.

Conclusion

In wrapping up our exploration of hot melt adhesives, it’s clear that these versatile bonding agents play a crucial role across various industries. From packaging to automotive applications, understanding what is hot melt adhesive and its implications can greatly influence production efficiency and product quality. The advantages of using hot melt adhesives are numerous, including their quick setting times and strong bonds, making them a preferred choice for many manufacturers.

Key Takeaways on Hot Melt Adhesives

To summarize, what is industrial hot melt adhesive made of? These adhesives are typically composed of thermoplastic polymers that offer excellent adhesion properties when heated. Moreover, the question of what is industrial hot melt adhesive used for can be answered with a broad range of applications—from consumer goods to construction materials—showing their adaptability in real-world scenarios.

Hot melt adhesive uses extend beyond mere bonding; they also enhance product durability and streamline manufacturing processes. Understanding how does hot melt glue work involves recognizing its unique properties that allow for rapid application and bonding upon cooling. Ultimately, the key takeaways highlight the importance of selecting the right type based on specific needs to maximize performance.

Future Trends in Hot Melt Adhesive Technology

Looking ahead, innovations in hot melt adhesive technology promise exciting advancements that could reshape industries further. One trend is the development of eco-friendly formulations that maintain performance while reducing environmental impact—a growing concern among consumers and manufacturers alike. Additionally, advancements in application techniques will likely enhance how we understand how does hot melt glue work, leading to even more efficient processes.

As industries evolve, so too will the applications for what is industrial hot melt adhesive used for; expect to see integration with smart technologies and automation systems in manufacturing settings. Furthermore, research into new raw materials could expand the possibilities of what is hot melt adhesive capable of achieving in specialized sectors like healthcare or electronics.

Final Thoughts on Choosing the Right Adhesive

Familiarity with what is industrial hot melt adhesive made of helps inform decisions about durability and compatibility with materials involved. Remember that understanding both how does hot melt glue work and its practical applications ensures you select an optimal solution tailored to your needs.

In conclusion, whether you’re a seasoned professional or just diving into this world, keeping abreast of trends will help you harness the full potential of these adhesives while considering future developments within this dynamic field.